Curvecrete awarded Accelerating Commercialisation Grant

Curvecrete render by Swinburne intern, Daniel Shawyer

In summary

- Swinburne lecturer in architectural engineering, Daniel Prohasky has received funding for robotic curved concrete moulding

- Curvecrete helps to embrace zero waste via advanced manufacturing and fit-for-purpose robotic technologies

Swinburne lecturer in architectural engineering and co-founder of Curvecrete, Daniel Prohasky with co-founder Warren Rudd have won an Accelerating Commercialisation Grant from the Australian government.

Simpler, faster and zero-waste production

Swinburne awarded Prohasky was a Swinburne Innovation Fellow in 2019, for his work in establishing and developing Curvecrete. With Swinburne’s support, Curvecrete has created a robotic concrete moulding technique to produce bespoke curved concrete panels – making production simpler and faster with zero waste.

The $325,158 grant will assist Curvecrete to develop a pilot manufacturing facility in Melbourne.

Video by Swinburne Curvecrete intern Daniel Shawyer, Travis Gemmill, Marcus Cher, Paul Meeuwsen and Daniel Prohasky.

Multiple and flexible applications

Curvecrete panels can be used in non-structural cladding applications like facades, rain screens and non-combustible cladding replacement; in structural applications – modular curved homes, urban art work, seating and balustrading; and in infrastructure – curved pedestrian bridges, highway sound barriers and pylons.

The Swinburne Innovation Precinct supports Curvecrete’s focus on accelerating Australia’s construction industry to embrace zero-waste, with low or zero embodied carbon emissions, via advanced manufacturing and fit-for-purpose robotic technologies.

Prohasky also works with the Precinct and School of Design and Architecture to encourage students to participate in Swinburne’s Venture Cup and Accelerator Program.

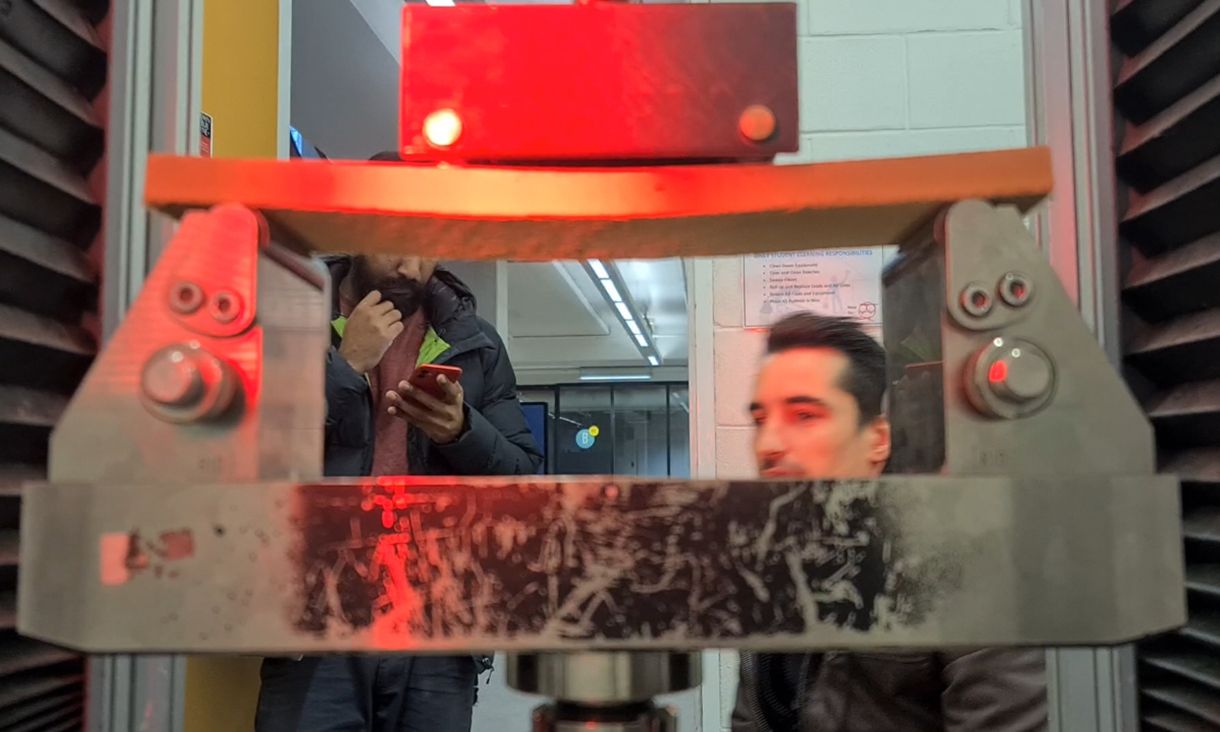

Prohasky (right) testing concrete in the lab at Swinburne.

Low-carbon cement alternatives

His role as Robotics in Construction theme leader at Swinburne’s Smart Cities Research Institute has led to collaboration with Swinburne’s Digital Construction Laboratory – supporting Curvecrete’s mission to use low-carbon cement alternatives.

Curvecrete has subsequently developed expertise in creating commercially viable low-carbon, light-weight fibre-reinforced geopolymer concrete. It is building on research in geopolymer materials development at DCL, for real-world scenarios as non-combustible cladding with official AS1530.1 compliance.

Algorithmically CNC milled geopolymer, image supplied by Daniel Prohasky

Students helping to solve the construction waste crisis

Swinburne students have assisted Curvecrete through internships and industry projects. Design students have developed media and branding content to promote Curvecrete’s mission to help solve the construction waste crisis in a beautiful way.

‘Getting the word out is important to Curvecrete. We want to engage with property developers and private clients looking to build something innovative using sustainable modes of construction can be beautiful!’ says Prohasky.

Advanced manufacturing and fit-for-purpose robotic systems

‘Curvecrete’s new factory will be an advanced manufacturing facility,’ he adds. ‘We’re expanding our manufacturing capabilities to deliver on multiple commercial and infrastructure projects.’

The facility is a huge step in the right direction for scaled manufacture of low carbon construction, enabled through fit-for-purpose robotic systems.

‘Curved architecture has been imagined by architects for centuries. It’s always been complex to build. Curved forms like the Sydney Opera House inspire us,’ says Prohasky.

Traditionally, manual formwork needs to be constructed to create a form to cast concrete. The material and labour required to create formwork is generally discarded after one use. ‘Adaptive mould technology or robotic formwork that’s completely reusable eliminates this waste and effort, making the process simpler and more cost effective,’ explains Prohasky.

He envisions a more sustainable future enabled by making curvature in a totally reusable way. ‘Traditionally manufactured curvature for architecture is like manually building a boat then discarding it when you get to your destination!’

In the not-too-distant future, he hopes to make curved architecture at cost parity with flat panels, and continue to develop manufacturing techniques that minimise waste.

‘Reducing Australia’s construction waste stream is a huge shared goal to avoid and help reverse environmental contamination,’ says Prohasky.

Want to discover more about what the future holds for Curvecrete? What Is The Future For Cities is a podcast created by architect and Swinburne PhD candidate Fanni Melles. In this episode, she interviews Prohasky about what lies ahead for Curvecrete.

-

Media Enquiries

Related articles

-

- Design

- Astronomy

- Technology

- University

Swinburne ‘Rock Muncher’ takes part in Australian Rover Challenge

A multidisciplinary student team from Swinburne University of Technology competed in the 2024 Australian Rover Challenge held in Adelaide, South Australia.

Thursday 11 April 2024 -

- Technology

- Education

- University

From humble beginnings to global impact: what Quitch did next

Dr Grainne Oates transforms Quitch from startup to global powerhouse, redefining education with Swinburne's support.Friday 01 March 2024 -

- Technology

CSIRO and Swinburne level up Australia’s manufacturing sector with Industry 4.0 Testlab

The Testlab has showcased its world-first fully automated industrial-scale production facility using a 3D-printing approach to composite component creation.

Read more (CSIRO and Swinburne level up Australia’s manufacturing sector with Industry 4.0 Testlab )Wednesday 13 March 2024 -

- Technology

World first project could see EVs charge wirelessly on the road

A $3 million grant by the Australian government will implement dynamic wireless charging technology into roads, unlocking the uptake of electric heavy vehicles and saving $324 billion by 2050.

Friday 16 February 2024 -

- Technology

- Science

- Sustainability

- Engineering

CSIRO and Swinburne invest in green steel and mineral processing to help industry get to net zero

CSIRO and Swinburne have established a new partnership to tackle global decarbonisation with innovative green steel and mineral processing research and development.

Thursday 01 February 2024