Digital Construction Laboratory

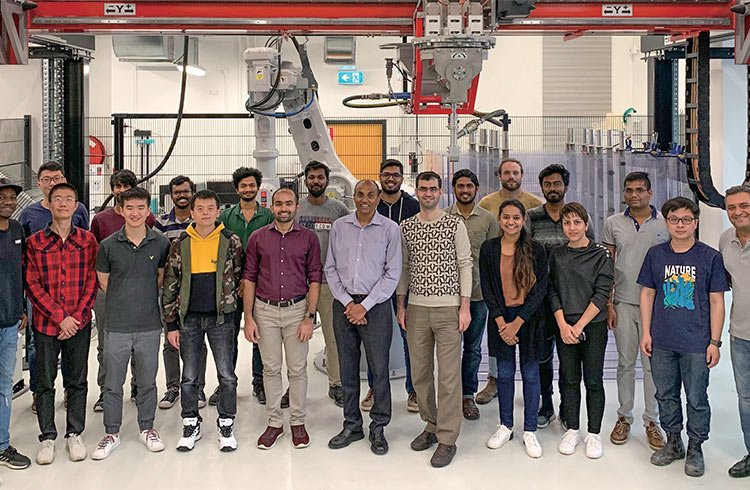

Swinburne’s Digital Construction Laboratory engages researchers and the construction industry to explore next generation construction methods and technologies using digital methods.

The recently established $2M state-of-the-art Digital Construction Laboratory is the only one of its type in Australia. It is part of the Centre for Sustainable Infrastructure and Digital Construction and has been developed for researchers and construction industry practitioners to explore next-generation of construction methods using digital technologies

The facility houses a wide range of 3D printing machines and robots for research and development on different 3D concrete printing technologies. 3D concrete printing is a rapidly emerging field of research with great promise to introduce the much-needed automation in construction. Several research groups and innovative construction companies are currently advancing this free-form construction technology worldwide.

Current projects include:

- investigation of cementitious materials for powder-bed 3D printing

- development of 3D printable geopolymers for digital construction

- interlayer bond strength and reinforcing methods in digital construction

- numerical simulation of 3D concrete printing

- development of ultra-high-performance concrete for digital construction

- development of aggregate-bed 3D concrete printing process

- enabling set-on-demand in concrete for extrusion-based digital fabrication

- active rheology control in concrete for digital construction.

Equipment

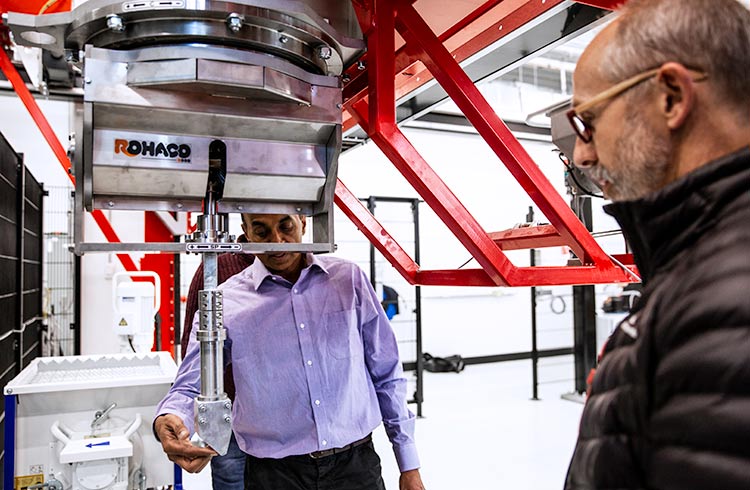

Large-scale 6-axis gantry 3D concrete printer

This 3D concrete printer is the only one of its kind in the world equipped with a 6-axis nozzle for maximum design freedom which allows 3D printing of large-scale concrete structures on a curved surface using extrusion technology. The printer has a build volume measuring 8.0 m (L) x 5.0 m (W) x 2.8 m (H). The printing speed ranges from 0 to 1200 mm/s, with a concrete flow rate of 0.5 – 8 litres per minute.

The width of each printed layer can vary from 1.2 cm to 6.0 cm. This printer has a full CNC control mechanism and a fully integrated concrete mixing and pumping system.

Large-scale industrial ABB robot

The ABB IRB6700 robot is one of the highest performance robots, which has a payload from 155kg, reaches 2.85 metres, with a wrist torque of 927 Nm.

Medium-scale 4-axis gantry 3D concrete printer

This printer is equipped with a 4-axis nozzle allowing 3D printing of medium-scale concrete structures on a flat surface using extrusion technology. The printer has a build volume measuring 1.8 m (L) x 1.2 m (W) x 1.8 m (H). The printing speed ranges from 0 to 100 mm/s.

Small-scale 4-axis gantry 3D concrete printer

This printer is equipped with a 4-axis nozzle allowing 3D printing of small-scale concrete structures on a flat surface using extrusion technology. The printer has a build volume measuring 1.0 m (L) x 1.0 m (W) x 1.0 m (H). The printing speed ranges from 0 to 100 mm/s.

Large-scale powder-bed printer

This printer contains 1000 nozzles and the distance between the nozzles is 3 mm. It is suitable for printing high-resolution large-scale samples using powder-bed technology. The printer has a build volume measuring 1700 mm (L) x 1300 mm (W) x 1500 mm (H). The printing speed is 60 mm/sec (in vertical direction). The resolution of the printer is 2 mm.

Small-scale powder-bed printer

This printer is suitable for printing high-resolution small-scale samples using powder-bed technology. The printer has a build volume measuring 236 mm (L) x 185 mm (W) x 127 mm (H). The printing speed is 20 mm/hour (in vertical direction). The resolution of the printer is 300 x 450 dpi with a minimum feature size of 0.4 mm.

Viskomat XL rheometer

This is a rheometer for mortar and fresh concrete with a maximum grain size of 8 mm. The speed ranges from 0.0001 to 80 rpm in both directions. This rheometer has a torque ranges from 0 to 1000 Ncm with a resolution of 0.05 Ncm and accuracy better than 0.2 Ncm.

Contact

Professor Jay Sanjayan

Phone: +61 3 9214 8034

Email: jsanjayan@swin.edu.au