Intelligent Robotics Laboratory

The engine room for robotic research at Swinburne

Founded in 2021 by Associate Professor Mats Isaksson, with support from the Australian Research Council and the Innovative Manufacturing Cooperative Research Centre, the Intelligent Robotics Laboratory houses several research groups and includes a multitude of robots, including collaborative robots (cobots), industrial robots, parallel robots, mobile robots and humanoid robots.

The lab has a range of additional equipment including:

- 3D scanners

- depth and thermal cameras

- light detection and ranging (LiDAR)

- motors and actuators

- haptic devices

- microcontrollers.

The Intelligent Robotics Laboratory also boasts high-performance computing equipment and facilities for RAPID prototyping, including two 3D printers, and is conveniently located next to the Swinburne Protolab.

Current research projects focus on manufacturing robotics, robots for repair and recycling, agricultural robotics and medical robotics.

Our highlights

The Intelligent Robotics Lab is a hub for the Intelligent Robotics Program – one of the four research programs coordinated by Swinburne’s Manufacturing Futures Research Platform.

Key members of the Intelligent Robotics Program include:

The Intelligent Robotics Laboratory is the premier facility for the Victorian branch of the Australian Cobotics Centre, which is an Australian Research Council Training Centre for Collaborative Robots in Advanced Manufacturing.

To learn more about this collaboration between Swinburne, Queensland University of Technology and the University of Technology Sydney, visit the Australian Cobotics Centre website.

Researchers involved in the Swinburne branch of the Australian Cobotics Centre include:

- Associate Professor Mats Isaksson (Swinburne Lead and Program Co-leader – Biomimic Cobots)

- Dr Michelle Dunn (Program Co-leader – Quality Assurance and Compliance)

- Associate Professor John McCormick (Chief Investigator)

- Associate Professor Chris McCarthy (Chief Investigator)

- Dr Anushani Bibile (Postdoctorate)

- Mr Jagannatha Charjee Pyaraka (PhD student)

- Mr Idhant Bhambri (PhD student).

This research team is an established interdisciplinary collaboration between three Swinburne researchers and one laparoscopic surgeon.

The team has received significant funding from Mulgrave Private Hospital and Cambridge Medical Robotics to investigate the ergonomic benefits of robot-assisted laparoscopic surgery compared to traditional laparoscopic surgery.

The researchers include:

- Associate Professor Mats Isaksson (Robotics)

- Associate Professor John McCormick (Motion Capture)

- Associate Professor Indran (Chrys) Hensman (Laparoscopic Surgery)

- Dr Oren Tirosh (Biomechanics).

Although primarily a research lab, the Intelligent Robotics Laboratory is used by undergraduate students and Higher Degree by Research students in several units. Some students also volunteer to assist in various industry projects.

PhD candidates

Several PhD candidates have the Intelligent Robotics Laboratory as their permanent workplace – making it a high-energy workspace. These students include:

- Mariadas Roshan

- Jagannatha Charjee Pyaraka

- Kartik Choudhary

- Rene Santander

- Edgar Mauricio Hidalgo Florez

- Bhanu Watawana

- Xinbing Ding

- Nazanin Bassiri

- Idhant Bhambri

- Mehran Ahmadi.

Control Engineering (MEE30002)

The Intelligent Robotics Laboratory houses a hardware setup controlled by a programmable logic controller (PLC). The Control Engineering unit includes a group project to develop ladder programs for the PLC. We are also developing a solution to manipulate the PLC with an industrial robot teleoperated by students.

Robotics in Manufacturing (ADM80011)

This Robotics in Manufacturing unit is being modified for students to use the equipment in the Intelligent Robotics Laboratory.

Final Year Projects (FYRP1 and FYRP2)

Every year, the Intelligent Robotics Laboratory houses several final year student projects including:

- analysis of benefits of toroidal propellers

- analysis of optimal design of 2-DOF haptic devices

- development of a low-cost take-home experimental platform for students in Control Engineering unit to implement a PID controller in a microcontroller.

International visits

The Intelligent Robotics Laboratory welcome long-term internships by external PhD candidates. Visitors include Siripong Pawako and Nattawat Yachum from Suranaree University of Technology, Thailand.

Our world-class research equipment

Medical robotics

The Intelligent Robotics Laboratory facilitates a range of research projects focusing on medical robotics. It is the home of a renowned research group that studies the ergonomic benefits of robot-assisted laparoscopic surgery.

It also houses research collaboration between Swinburne and Baker Heart and Diabetes Institute to develop a teleoperation solution for heart ultrasound examinations.

Other project teams are developing prototypes for robotic photobiomodulation therapy of chronic pain, autonomous ultrasound examinations, robotic skin cancer detection and robotic 3D scanning of patients.

Our equipment and infrastructure includes:

- one UR5e robot from Universal Robots

- one Phantom Omni haptic device

- one FLIR A50 thermal camera

- several Intel RealSense D415 depth cameras

- one Clarius HD C3 wireless ultrasound probe

- one large custom-built turntable

- one Artec Eva 3D scanner

- one Revopoint POP 2 3D scanner

- one Revopoint range scanner

- one Canon EOS R camera

- one SLAMTEC Mapper Pro Kit - Laser Mapping Sensor.

Collaborative robotics

The Inteligent Robotics Laboratory has an extensive range of collaborative robots (cobots) which are continually utilised for varying research projects. These include:

- one UR5e cobot from Universal Robots

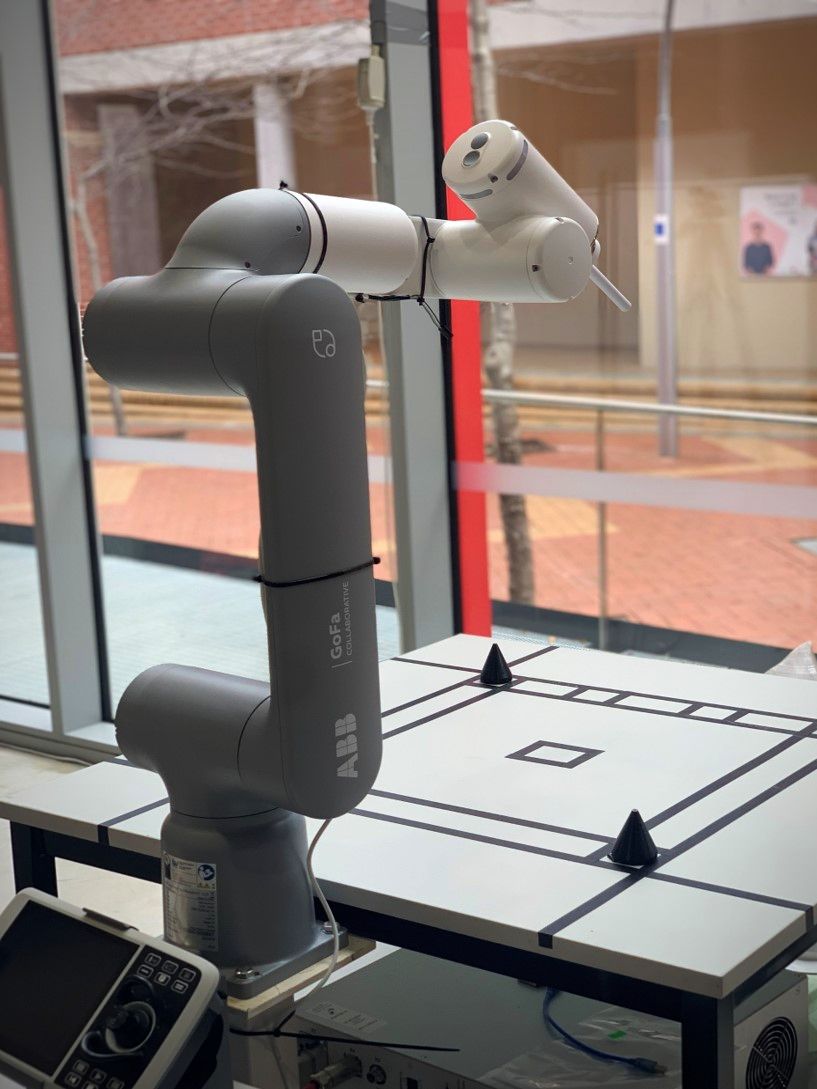

- one CRB 15000-5/0.95 (GoFa) cobot from ABB Robotics

- one Xarm6 cobot on a linear track from UFactory

- one Sawyer cobot from Rethink Robotics

- one MyCobot 280 cobot from Elephant Robotics.

GoFa cobot from ABB Robotics

Industrial robotics

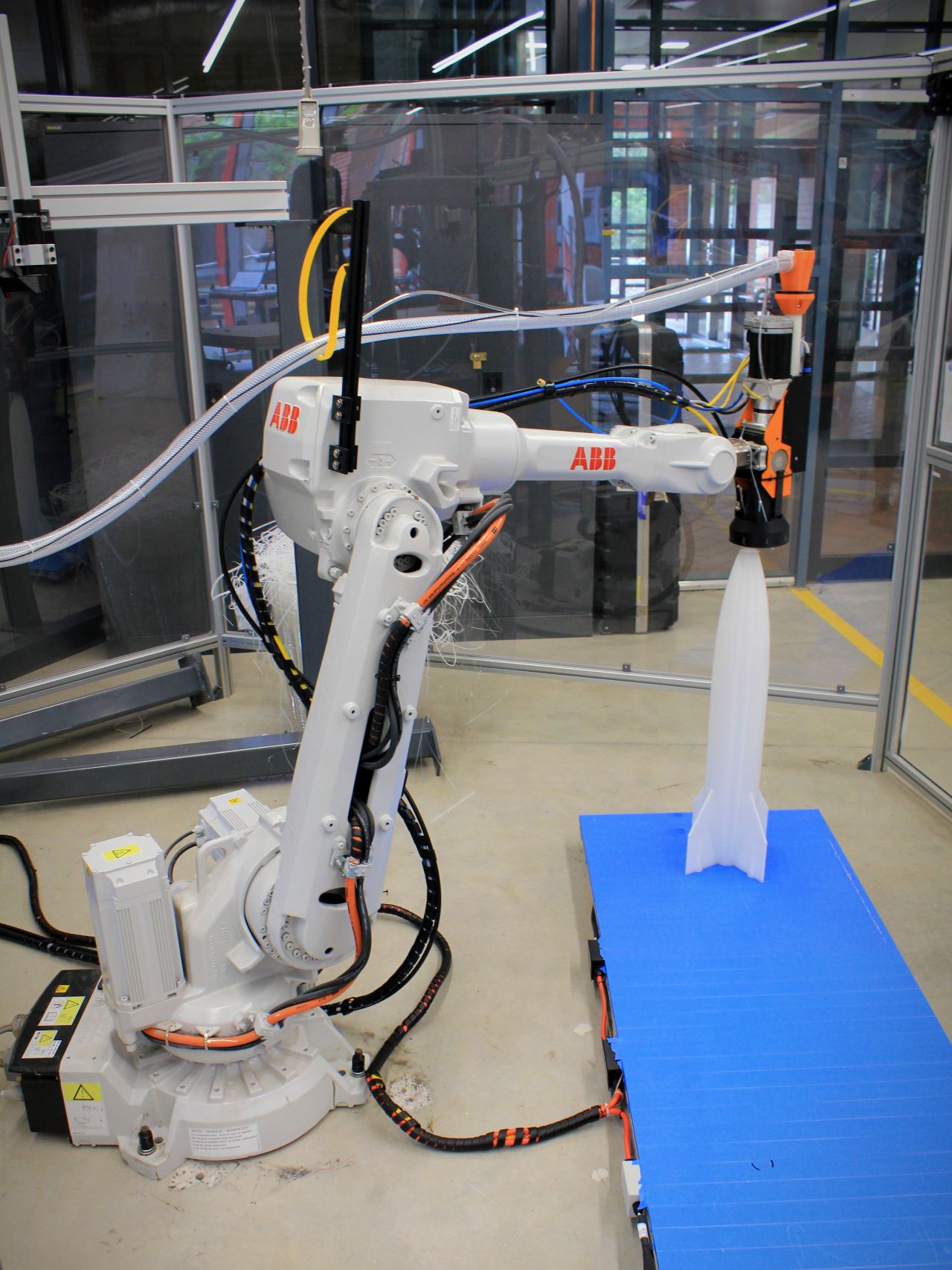

The Intelligent Robotics Laboratory houses an ABB IRB 2600 industrial robot with 20-kilogram payload capacity. The robot cell was previously used in a $1 million IMCRC project to develop a solution for the automatic repair of car headlights.

It is now used in a project funded by the Australian Defence Institute to develop a large-scale 3D printer for the creation of biofouling-resistant large-scale parts with the aid of antifouling thermoplastic material. The lab has also recently received an ABB IRB 140 which will be used in a teleoperation project.

Our equipment and infrastructure includes:

- one ABB IRB 2600 industrial robot

- one Massive Dimension Pellet Head 2 Extruder (MDPH2)

- one Massive Dimension Material Conveyance Unit (MDMCU)

- one Massive Dimension Feedstock Agitator

- three 1600 W 660 x 660 mm heated beds and PID controllers.

A robotic 3D printing setup

Need more information?

If you’re a student, media professional or an organisation looking to access our facility or partner with us, please get in touch by emailing Associate Professor Mats Isaksson at misaksson@swinburne.edu.au.