Sustainable shopping: students develop products with fungi

A group of budding engineers and designers have created sustainable shop fittings and displays for leading eco brand Seed & Sprout, as part of a Swinburne internship.

In summary

- Design, architecture and engineering students have taken part in a professional internship to design and grow products for leading eco brand Seed & Sprout

- Mycelium was used to create the products, ranging from product packaging to furniture

- The project won a prestigious Good Design Award Best in Class accolade

A group of budding engineers and designers have created sustainable shop fittings and displays for leading eco brand Seed & Sprout, as part of a Swinburne internship.

Using mycelium, the root structure of fungi, the twelve students designed and grew the objects for the brand’s Byron Bay pop up shop, ‘Made+Mycelium’.

The project has already launched the students into the spotlight, winning a prestigious Good Design Award Best in Class accolade.

Participating in the project were students Adele Easton, Bailey Harper, Dilan Yariz, Fifi Prayogo, Harry Tweedale, Hayley Boicovitis, Jack Arceri, Louis Ryan, Luka Markulin, Marianne Coetzee, Megan Lambert and Tyson Morgan. They were supervised by Swinburne Architectural Design Lecturer Canhui Chen and Associate Professor John Sadar.

-

Adele Easton with mycelium light feature

Adele Easton with mycelium light feature -

Mycelium décor objects made by Swinburne students

Mycelium décor objects made by Swinburne students -

Dilan Yariz with Mycelium stools/planters

Dilan Yariz with Mycelium stools/planters -

Mycelium lampshades made by Swinburne students

Mycelium lampshades made by Swinburne students -

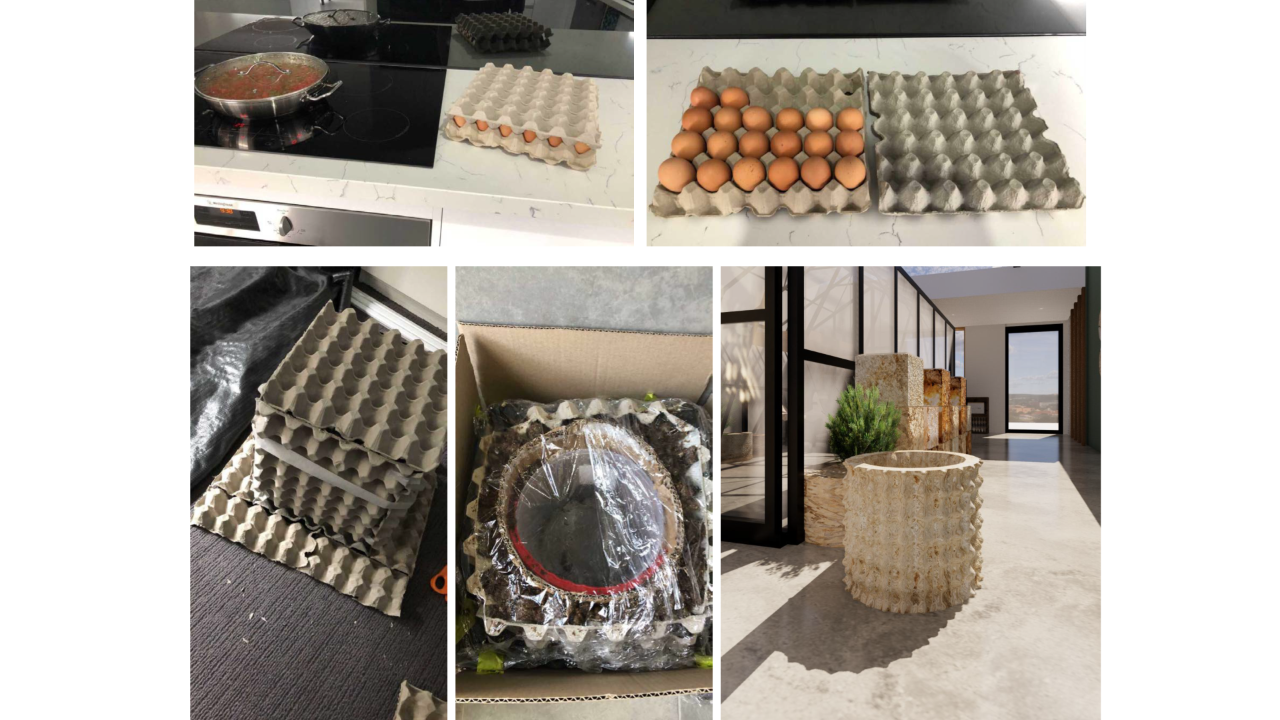

Custom mycelium product packaging developed by Swinburne students

Custom mycelium product packaging developed by Swinburne students -

Mycelium pliths made by Swinburne students

Mycelium pliths made by Swinburne students

Adapting to change

The project began in mid-2021 as a professional internship offered to architecture, design and engineering students. The challenge of mastering a curious, dynamic material was compounded by successive COVID-19 lockdowns, which forced students to work remotely and use found objects such as hard rubbish in their own neighbourhoods.

Chen delivered bags of hard product to the students, which they had to break down into a soil-like consistency and compact against frames or guides to train the growth in the shape of their designs. The structures were then wrapped in plastic for several weeks to grow, before being dehydrated (often in ovens or microwaves) to stop the growth process when the mycelium reached its target size and shape.

“Mycelium is unprecise and has a mind of its own,” Bachelor of Engineering student Adele Easton said.

“To then try and tame it and make it into a more precise object is very difficult. Cleanliness is a key factor too; before the mycelium objects are fully dehydrated, it can grow mould if placed in the wrong environment.”

Easton produced a light installation, combining her engineering skills to embed LED light strips to disk-shaped mycelium features. Other students grew lampshades, stools, bowls, planters, and even product packaging.

“It’s definitely a sustainable material, and a renewable one,” Easton said. “But maintaining precise control over the growing conditions, including a sterile environment, would make it challenging to grow on a production level.”

-

Growth process of mycelium plith

Growth process of mycelium plith -

Growth process of mycelium light feature

Growth process of mycelium light feature -

Growth process of mycelium planter

Growth process of mycelium planter -

Growth process of mycelum planter 2

Growth process of mycelum planter 2 -

Growth process of mycelium containers

Growth process of mycelium containers

Career-ready experience

The research into designing with mycelium composite at Swinburne started in 2018, led by staff in architecture. In 2019, students collaborated with a Spanish architectural institute to investigate implementing the material in sustainable building practices. In 2021, researchers developed floating mycelium pods to promote biodiversity at Melbourne’s Royal Botanic Gardens, and won a Good Design Award for their work.

Chen, who led the 2019 and 2021 projects, says Seed & Sprout approached Swinburne’s School of Design with the Made+Mycelium opportunity after the 2021 research.

“We were able to run it as a professional internship program, where students from various backgrounds can collaborate and work together as a team and work on real-world projects,” he said.

“It was a real project with a real client, deadline and budget. You can think of it as we were running a design firm and were commissioned by the client to deliver the pop-up store, and we hired a few students via the professional internship program. In this case, the students involved in the project were not considered 'students' but professionals working in a real project environment. It’s fantastic experience for the team to learn how concepts are turned into reality.”

-

Media Enquiries

Related articles

-

- Design

- Astronomy

- Technology

- University

Swinburne ‘Rock Muncher’ takes part in Australian Rover Challenge

A multidisciplinary student team from Swinburne University of Technology competed in the 2024 Australian Rover Challenge held in Adelaide, South Australia.

Thursday 11 April 2024 -

- Design

Swinburne and Scope design accessible USB hubs to improve lives

Swinburne’s Centre for Design Innovation has been researching and designing technology to improve the lives of those living with disability.

Tuesday 02 January 2024 -

- Trades

- University

- Sustainability

Transforming Indigenous housing with future-forward solutions

Swinburne University of Technology has launched a new Indigenous Building Co-Fab initiative. The initiative will tackle housing affordability and sustainability by creating innovative pathways to upskilling communities themselves.

Tuesday 19 December 2023