Manufacturing materials of the future – Smart composites

In Summary

- With the advent of composite materials, manufacturing is undergoing a huge change

- Graphene is the component that makes composite materials ‘smart’

- Graphene+ 2018 conference will examine applications for graphene as a component in the future of industry

Manufacturing materials are undergoing a huge change, particularly with the advent of composite materials that include components such as carbon fibre and graphene.

Composite materials have been around since mud and straw were mixed together to build ancient bricks. Concrete and fibreglass are also among the long line of materials that are stronger or more useful combined than in their constituent parts.

“The latest BMW I3 and I7, and about 50 per cent of the Boeing 787 are now made out of carbon fibre composites,” says Dr Nishar Hameed, a Group Leader at Swinburne’s Manufacturing Futures Research Institute and specialist in next generation of ‘smart’ polymers and composite materials.

“Carbon fibre based composites are used because they are eight times lighter than steel.”

These lighter materials for cars and planes – previously made from steel and aluminium – mean that the vehicles use less energy. The reduction in fuel use also reduces costs and carbon emissions. Naturally, the automotive, aerospace, mining, construction and other industries are all deeply interested in the potential of these materials.

Understanding smart composites

The next step is into smart composites.

“Most composites are not smart. They’re just ‘dumb’ materials that don’t share information,” says Dr Hameed.

“We can integrate sensors into smart materials so that we can learn about their performance, durability, structure and whether they are experiencing stress or damage. Smart materials are living materials.”

Graphene is the component that makes composite materials smart. A highly conductive nanomaterial, when graphene is embedded in steel, concrete or fabric – it can conduct electric signals, allowing it to act as a sensor.

Graphene made from graphite can be made into nano-platelets, which means it can be produced in high volume at low cost. The graphene can be added in small amounts to make nearly any composite conductive, sensing and smart.

Exploring the possibilities

Dr Lachlan Hyde, a research engineer, is excited about the possibilities.

“You can put them into liquids. You can paint it on the wall and turn your wall into a sensor. You can add it to carbon fibre and make that a sensing material as well. Think about an aeroplane that can give you real time feedback on its aerodynamics,” he says.

“The material will be able to tell you about the performance of large structures,” confirms Dr Hameed.

“It will be able to predict when maintenance is required as well as when damage has occurred, before it becomes critical.”

Testing the limits

Professor Franz Konstantin Fuss is Swinburne’s sensor expert in these projects. His team is testing smart composite materials to see how they respond to electrically to mechanical stimuli, testing the characteristics of their technical properties under load and stress, and ensuring that when the material deforms or starts to break down, it’s emitting a clear electrical signal.

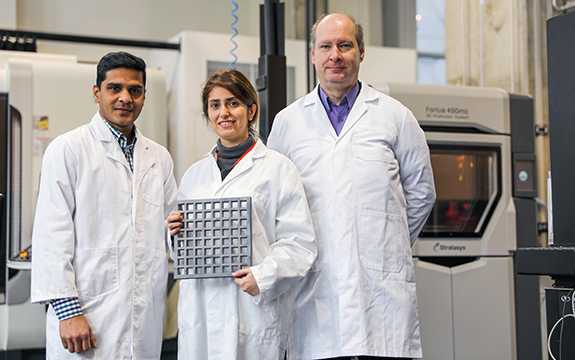

Swinburne’s smart composite team Dr Nishar Hameed (project leader), Mojdeh Reghat (PhD student) and Professor Franz Fuss (sensor expert) with a 3D printed prototype.

Swinburne’s smart composite team Dr Nishar Hameed (project leader), Mojdeh Reghat (PhD student) and Professor Franz Fuss (sensor expert) with a 3D printed prototype.

“If we don’t know what the materials’ or structures’ internal conductive paths are, we can’t interpret the signal,” says Professor Fuss.

“Once we can process and analyse the data, you can send the result to the manufacturer for improvement of the manufacturing process. Probably the most important applications are in the aerospace and automotive industries.”

Smart fabric applications

The technology has applications in the mining industry that have already been commercialised.

A smart fabric has been developed by Swinburne’s industry partner Imagine Intelligent Materials (Imagine IM) for use in the mining industry.

The ‘geotextile’ is coated with a layer of graphene-. The fabric can detect even small amounts of ground movement, heat or moisture indicating defects in dams and tunnels, alerting monitoring systems to any potential leak in tailing dams, for example, which contain toxic waste products.

“A leak can cause untold environmental damage and cost mining companies millions in restitutions. Imagine IM did a successful trial for leak detection using this smart composite fabric with a graphene based sensor,” says Dr Hyde.

A car seat that reacts to you

Imagine IM has used similar graphene-enhanced fabric to create a prototype smart car seat as part of the Stuttgart-based Startup Autobahn collaboration platform. Imagine IM’s smart fabric for car seats act as a sensor that reacts to and reports back on motion and touch. The car can tell whether a child or adult is in the seat and if someone has left a parcel on the back seat and feed that information back to the airbags. A textile seat sensor can control various functions of the seat and the car.

“In our demonstration, you don’t have buttons and switches, you just swipe the side of the seat and the seat moves. The textile becomes the interface,” says Imagine IM CEO, Chris Gilbey.

“This is about the internet of materials, not the internet of things. This goes beyond the individual widgets that send data. It’s about every surface being a sensing, reporting material and becoming a human-machine interface – a programmable surface.”

Imagine IM is a leading industry partner in Swinburne’s graphene certification centre, which is headed by Dr Hyde. The project aims to ensure graphene meets strict quality standards so it can be adopted into large-scale manufacturing.

“Graphene is poised to revolutionise many industries, but right now we need to answer the fundamental questions that arise when you integrate a novel material into production environments.” says Dr Hyde.

Graphene+ conference

On 8 October, the Australian Graphene Industry Association (AGIA) is holding the Graphene+ 2018 conference in Melbourne to examine the applications for graphene as a component in the future of industry.

Speakers will include Chris Gilbey and Swinburne’s Director the Manufacturing Futures Research Institute, Professor Bronwyn Fox.

AGIA was founded by Swinburne University of Technology along with Imagine IM, Geofabrics Australasia and Ionic Industries.