Partnering with Swinburne: EntroMat's startup success

Through co-creating with Swinburne and participating in the Founder-in-Residence program, EntroMat accelerated their pathway from research to commercialisation.

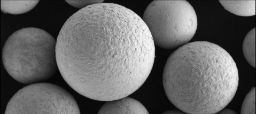

EntroMat is a Swinburne spin-out and deep-tech startup, producing High Entropy Material (HEM) powders – a new class of engineered materials – designed for extreme performance and durability combined with sustainability, developed from recycled industrial feedstocks.

The team's patented technology is tailored for additive manufacturing, surface-engineered coatings or powder metallurgy components – ideal for use across mining, energy, aerospace, medical technology and other applications.

By accelerating via Swinburne's venture programs and participating in Swinburne Innovation Studio's Founder-in-Residence (FiR) program, EntroMat has been supported to:

- co-create and develop their new business venture

- connect with investors

- launch into the market

- obtain pre-seed investment from Swinburne Ventures and Breakthrough Victoria through the BVUIP Co-Investment Platform.

EntroMat's partnership with Swinburne

Founder-in-Residence program

During this 12-month program for experienced entrepreneurs, EntroMat's academic co-founders were paired with an experienced FiR who supported the team to commercialise their technology and develop the business plan and commercial strategy for the spinout company.

Early-stage funding

Swinburne has invested in EntroMat through Swinburne Ventures Limited. Providing $1 million in joint funding with Breakthrough Victoria through the BVUIP Co-Investment Platform.

Business services

Through their commercialisation partnership with Swinburne's Innovation and Enterprise, EntroMat has benefited from a range of business services, including legal, financial and grant development support.

A deep-tech startup, driven by sustainability

EntroMat is a game-changer for Australia's sovereign capabilities. Using recycled industrial feedstocks and scrap metals, EntroMat produces next-generation alloys – tailored to business and industry needs.

"A simple application is for an excavator digging in the ground," EntroMat CEO Greg Lindsay explains. "If you're excavating, you're going to wear out the teeth on the bucket. If you coat the teeth with a High Entropy Material – and we can design it specifically for that application – then it won't wear out as quickly."

Exceptional durability is just one possibility. Through combining multiple principal elements, EntroMat's alloys can provide thermal stability, enhanced conductivity, as well as resistance to corrosion, wear, bio-fouling and radiation.

"The unique capability at Swinburne is to tune the design or the composition of the material to suit various applications," Greg says. "Because if you've got five or more elements, and you take the whole periodic table to choose materials, you've got trillions of combinations. The opportunity for us is to design the most optimum material for an application and provide the properties that the customer wants."

From a chance meeting to startup success

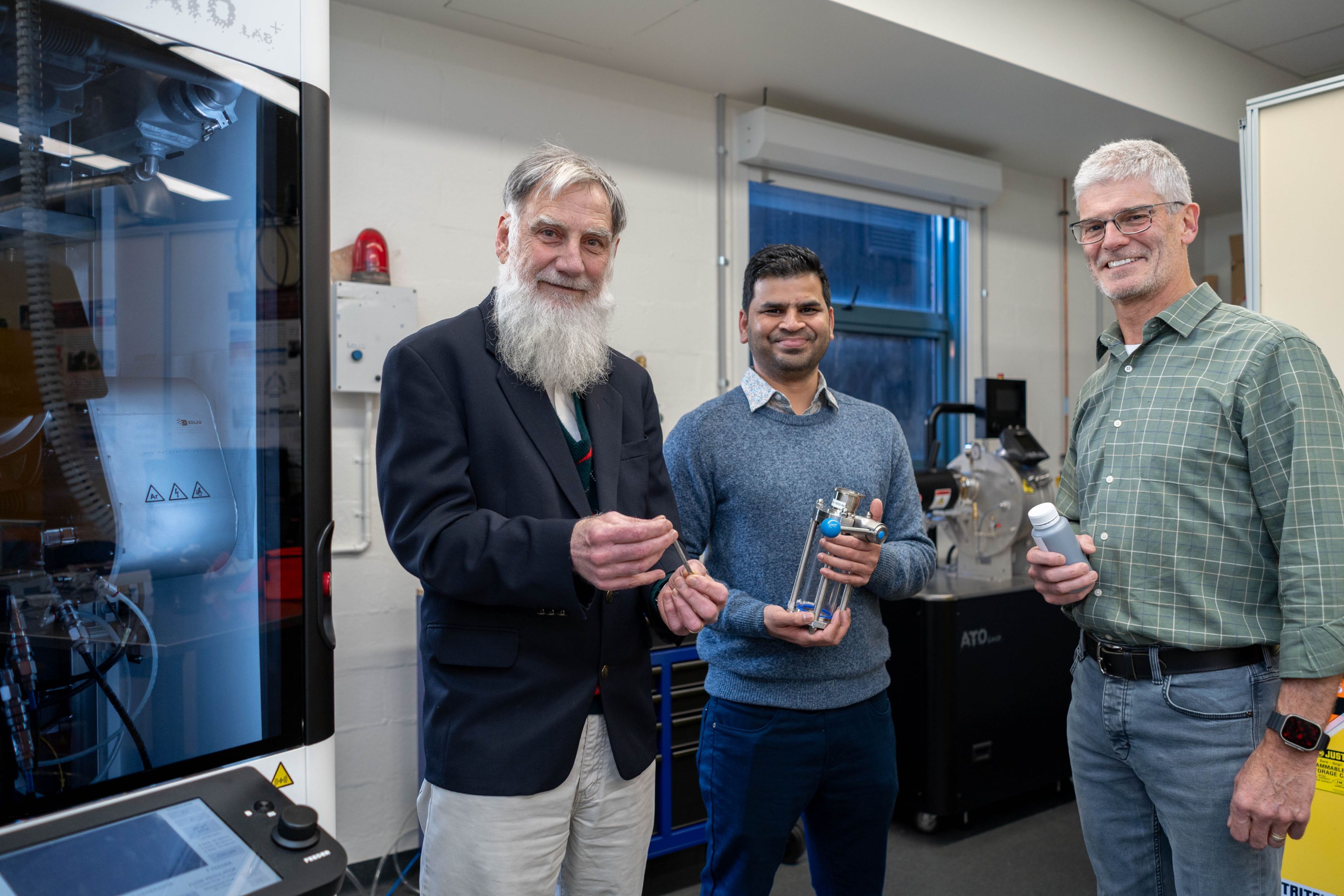

So, where did it all begin? Flash back to Avalon Airshow 2023. It was here that Greg first connected with Associate Professor Andrew Ang, EntroMat's co-founder and co-director of Swinburne's Space Technology and Industry Institute – a meeting that Andrew describes as one of the most significant in his life, second only to meeting his wife.

Since then, alongside fellow EntroMat's co-founders Professor Christopher Berndt and Dr Ashok Meghwal, they've been, as Andrew says, "four people that really believe in the vision of creating a sustainable route for manufacturing advanced materials."

The team capitalised on Swinburne's Innovation and Enterprise capabilities to turn their scientific research into a viable commercial venture. The biggest benefit of partnering with Swinburne, according to Ashok, was being able to ensure they were not "wasting their time commercialising something which is not going to be used in the future".

"Being an academic, we often just think about publishing a paper," Christopher explains. "But this is not about publishing papers. It's all about business."

-

“With vital early-stage funding for deep-tech startups like EntroMat, we ensure strong research can create benefit for industries at scale, sooner.”

Dr Werner van der Merwe , Vice President of Innovation and Enterprise, Swinburne University of Technology

Leveraging commercialisation opportunities at Swinburne

As part of EntroMat's venture acceleration with Swinburne's Innovation and Enterprise, Greg participated in Swinburne Innovation Studio's Founder-in-Residence program. "They gave us the time to be sure that we actually had an opportunity to pursue," Greg says. "They even brought in some initial investors. We were able to pitch and get a good understanding of where we could go."

Abhay Seth, Director of Commercialisation Innovation at Swinburne, says, "EntroMat is a great example of how we support researchers to take the leap from lab to market. With our new strategic focus on co-creating new industries, we partner innovators with our Founder in Residence and prepare them for investment, enabling our Commercial team to accelerate their spin-out journey. We're committed to ensuring Swinburne innovators are venture-ready, co-developing new sectors, and remaining competitive on a global stage."

Swinburne even took care of establishing EntroMat's term sheet and legal contracts. "It made it exciting for the founders to realise that we have free reign within reason to develop and commercialise these materials," Greg says. "It was a terrific opportunity to do this, and the Innovation and Enterprise team really did help support us and get us there."

Support has also been financial. EntroMat recently secured $1 million in joint funding from Swinburne Ventures Limited and Breakthrough Victoria through the BVUIP Co-Investment Platform.

More recently, Swinburne received $2 million in Federal Government funding through the Australia's Economic Accelerator (AEA) program. This is a landmark grant that Greg describes as "a transformative leap forward for Swinburne and EntroMat."

Coming full circle

In 2025, EntroMat launched at the very place it all started – the Avalon Airshow. As for the future, the team is looking forward to establishing their own factory, developing a portfolio of products and exporting up to 80 percent of what they manufacture. They'll do so with a solid grounding in business confidence gained through Swinburne's Innovation and Enterprise.

"They have always respected the founders," Ashok says. "That was very important for us – that they understood our point. We're coming from an academic background. We are not business or commercial people. They've been patient with us. Swinburne's Innovation and Enterprise always makes sure that the founders are the ones who benefit the most from this process."

Ready to innovate?

If you have any questions, need more information or want to know how we can help turn your big idea into a real thing, email us at innovationstudio@swinburne.edu.au.