Pioneering housing construction with 3D concrete printers at Swinburne

In Summary

This article originally featured in Swinburne's Research Impact magazine.

The transformative technology of 3D printing is shaking up many sectors of industry, but it’s nothing compared to the disruption coming to construction.

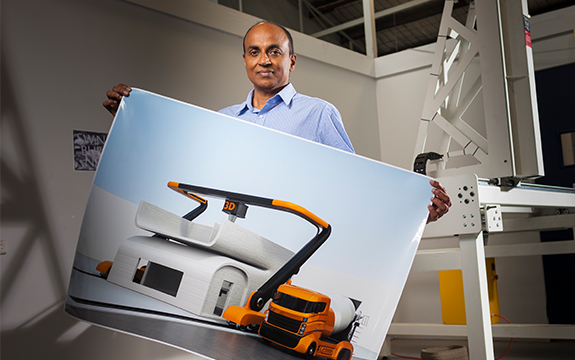

Professor Jay Sanjayan, Director of Swinburne’s Centre for Sustainable Infrastructure and Professor of Concrete Structures at Swinburne, leads a $1.3 million collaboration between seven Australian universities to develop 3D printing of concrete.

“Construction remains largely manual work, which makes it very expensive, and makes the global need for housing and infrastructure very hard to meet,” Professor Sanjayan says.

“Construction is open to be disrupted by automation, and 3D printing is one technology that can help.”

Although 3D printers are commercially available for manufacturing, there are significant differences between printing aeroplane parts and printing a house.

“Rather than factory conditions, we have to print out in the weather,” Professor Sanjayan said.

“Instead of a few kilos of materials, we have to handle tonnes. And although we don’t need the same accuracy as the aerospace industry, we have to trade that for low cost.”

To address the challenges, Professor Sanjayan has explored two approaches. The interim option is ‘powder bed’ 3D printing, in which the printer spreads a thin layer of concrete powder, then prints a water-based ‘ink’ that sets the concrete where the ink is applied.

Layer by layer, the process is repeated. The challenge was to automate the collection and reuse of the vast quantities of unreacted powder that each print run generated, Sanjayan said.

Powder bed was a good option for forming pre-cast sections of a building in a factory.

“We can make very intricate structures. But it was not a process that could take place out in the wind and rain.”

For on-site concrete printing, a machine is needed that extrudes liquid concrete, Professor Sanjayan said.

“Here, the main issue is the concrete itself,” he says.

The concrete must remain liquid inside the printer, but set as soon as it is printed to retain its shape and so the next layer can be applied.

Traditional concrete doesn’t behave this way. Currently, the most common approach is to heavily dose the concrete with chemical retardants that keep it liquid, then heavily dose with accelerators as it is extruded. But this approach compromises the mechanical properties of the finished product.

“We are coming up with new types of cement that have these properties intrinsically,” Professor Sanjayan says.

Though he’s not able to disclose the details yet, one option is to use a geopolymer cement, a material made from an industrial waste called fly ash.

“Architects already design everything by computer,” Sanjayan said. “Instead of printing their plans out on paper, with 3D printing we’ll just press a button and the machine builds it — that’s the ultimate dream.”

Learn more about the rapidly emerging field of 3D construction printing at the first International Conference on 3D Construction Printing (3DcP), hosted at Swinburne, 26-28 November 2018.