Swinburne and Amaero to work together on space technology

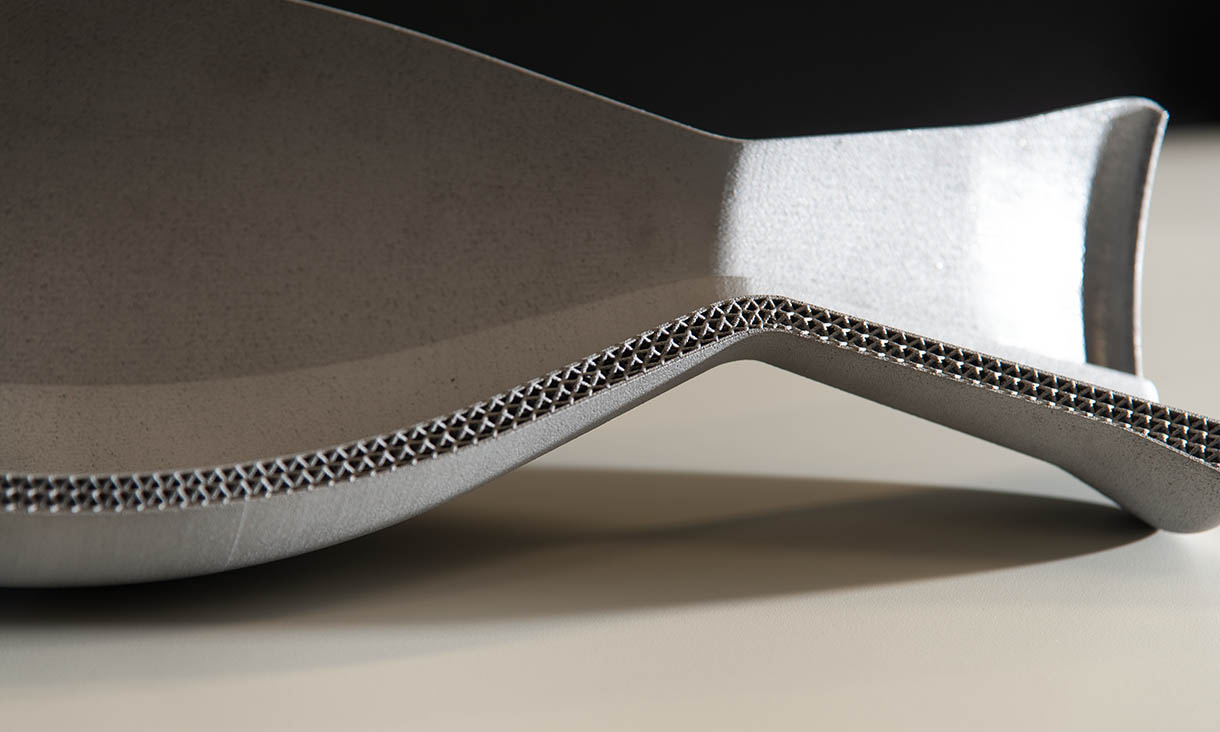

Swinburne and Amaero have established a research collaboration to jointly work on coatings for rocket engine components like this rocket nozzle.

In summary

- Swinburne and Amaero establish research collaboration agreement to jointly work on coatings for internal turbine engine surfaces and nozzles

- The collaboration will focus on developing and manufacturing coatings for use in extreme operating environments

- Research outputs will have commercial applications in aviation, space, defence and high temperature processing environments

Swinburne University of Technology and leader in metal additive manufacturing, Amaero International Limited have partnered with the Australian National Fabrication Facility Limited (ANFF) on a project to develop coatings for internal turbine engine surfaces and nozzles.

The project’s aim is to advance Compliant Multilayer Environmental Barrier Coatings (EBCs) that can be applied to rocket engine components. The outputs of the research will have commercial applications in aviation, space, defence, and high-temperature processing applications.

‘This is an exciting project that showcases Swinburne’s strength in materials and coatings for space,’ says Director of Swinburne’s Space Technology and Industry Institute, Professor Alan Duffy.

‘By bringing together the brightest minds and world class capabilities from Swinburne, ANFF, and local industry excellence in Amaero, we can address the material issues within the extreme environment of a turbine engine.

‘In solving this problem for space, we also benefit through its use back on Earth. Swinburne is delighted that Amaero is partnering with us in this breakthrough space manufacturing technology,’ Professor Duffy says.

Through the research collaboration Amaero will:

- Identify suitable 3D printed designs that allow for the construction of the EBCs

- Provide technical advice during manufacturing and performance testing

- Manufacture and provide of full-scale demonstrator parts to meet the EBC requirements

- Provide $150,000 (ex-GST) in funding over a 48-month period to support two PhD students and direct cost to work on this project as well as $150,000 of value in kind.

Swinburne will also contribute to the cost of the project and provide in-kind contributions, focusing on:

- Identifying EBC microstructures, designs, and alternative material systems to meet commercial relevant requirements and develop approaches to fabricate the identified EBCs

- Responding to industry expert’s feedback concerning optimisation of the microstructure for the EBC application

- Conducting fabrication trials that meet the commercial relevant EBC requirements.

‘We are very pleased to be collaborating with Swinburne University of Technology on researching and developing specific barriers and coatings,’ Amaero CEO, Barrie Finnin, says.

‘The global space industry represents a significant large and strategic commercial opportunity for Amaero and this research will enhance the industry-leading technology that our company provides. We look forward to working with Swinburne and the ANFF on this research and development project and benefiting from the commercial opportunities arising from the outcomes.’

The collaboration highlights the global significance of Australia’s research capability and the growing presence of Australian technology within the aerospace and additive manufacturing sectors.

-

Media Enquiries

Related articles

-

- Technology

- Science

- Engineering

Victorian students drive green energy transition through international hydrogen competition

Swinburne’s KIOSC, in collaboration with Horizon Educational and Gippsland Tech School, co-hosted the Hydrogen Grand Prix in Melbourne.Friday 26 July 2024 -

- Technology

- Health

New MedTechVic prototypes to transform everyday lives of people with a disability

Swinburne’s MedTechVic has revealed three new prototypes designed through the joint Health-led Manufacturing Innovation Program, in partnership with the Australian Medtech Manufacturing Centre and Safer Care Victoria

Friday 19 July 2024 -

- Business

- Technology

Swinburne’s Luminate Pitch Night 2024 advances innovative ideas for a better world

Swinburne’s 2024 Luminate Pitch Night showcased market-ready ideas from 10 founders

Wednesday 12 June 2024 -

- Health

- Technology

Clinical Innovation Fellowships develop creative solutions to Australia’s healthcare challenges

MedTechVic is gearing up to begin its fourth year of the Clinical Innovation Fellowship Program (CIFP), following the highly successful third round in 2023.

Wednesday 19 June 2024 -

- Technology

- Aviation

- Sustainability

Swinburne partners with Latrobe City Council to propel Victoria’s Advanced Air Mobility precinct

Swinburne has become the first Foundation Member of the newly established Latrobe Aerospace Technology Precinct.

Friday 03 May 2024