Ultra-thin lens breakthrough could revolutionise miniature cameras

Dr Han Lin and Professor Baohua Jia from the Centre for Translational Atomaterials have developed a lens that could revolutionise miniature cameras.

In summary

- An international team, led by researchers from Swinburne’s Centre for Translational Atomaterials, has developed an ultra-thin lens

- The lens could be used in eyeglasses, microscopes, magnifying glasses, and camera lenses

An international team, led by researchers from Swinburne’s Centre for Translational Atomaterials, has developed an ultra-thin lens that could revolutionise miniature cameras and high-speed photonic chips.

The lens is made from a one molecule layer of atomaterials – the next generation of nanomaterials with a thickness about one millionth of a human hair in size.

It could be used in ultra-compact cameras, achieving high resolution images comparable to state-of-the-art imaging systems.

The research breakthrough has recently been reported as the cover story in the Nature journal Light Science & Application. It was co-led by Founding Director of Swinburne’s Centre for Translational Atomaterials, Professor Baohua Jia, Professor Qiaoliang Bao formerly at Monash University, and Professor Chengwei Qiu at National University of Singapore.

“Lenses are the key element in optical systems in our daily life, including eyeglasses, microscopes, magnifying glasses, and camera lenses,” says first author Swinburne’s Dr Han Lin.

“Conventional lenses based on light refraction need multiple lenses to be stacked to form compound lenses to minimise aberrations and achieve good imaging quality. Therefore, current high-quality camera equipment is complex and bulky. We have put tremendous effort into the development of ultrathin flat lenses.”

Unlike conventional lenses, a flat lens uses nanostructures to control light and correct image distortion. It can also produce different light patterns to achieve functionalities like display, coloration or optical tweezers – scientific instruments that use a highly focused laser beam to hold and move microscopic objects.

However, when the lens becomes very thin – just a single layer of atoms, for example – it cannot provide good image quality with high resolution and high contrast.

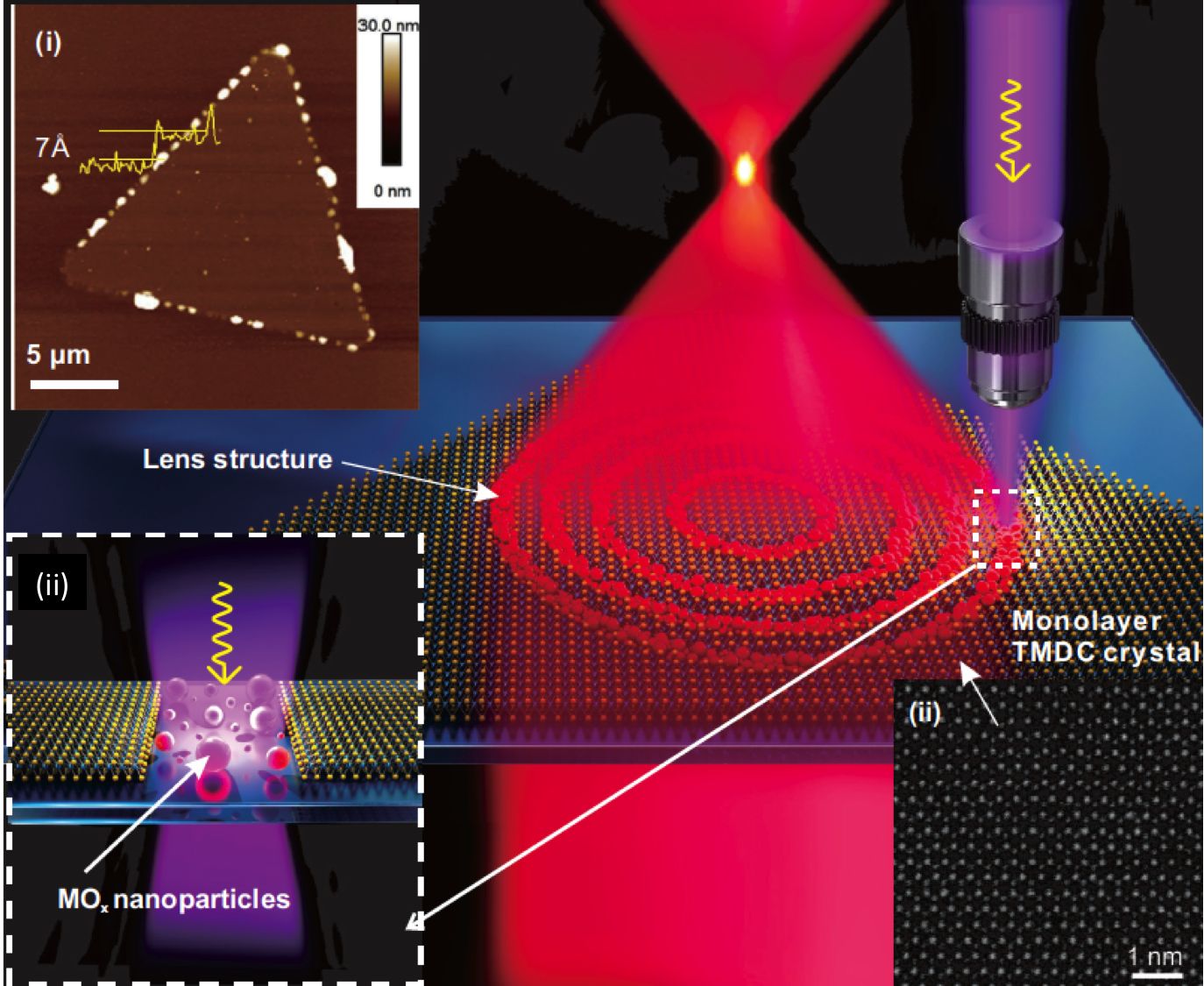

In this work, the researchers used a laser to nanoprint the surface of the monolayer materials to fabricate the lens. Unlike conventional lenses with a smooth curved surface, the monolayer lens is ultraflat and composed of concentric rings with a rough surface composed of nanoparticles (shown in the figure).

An atomaterial lens made by laser nanoprinting of a monolayer of transition metal dichalcogenide (TMDC) materials. Schematic of femtosecond laser nanoprinting of a monolayer TMDC lens. Inset: (i) AFM image of a monolayer TMDC single crystal, and (ii) Schematic of laser nanoprinting generation of nanoparticles assisting the high performance focusing.

This nanoprinting made the monolayer lens capable of providing high-resolution, high contrast images, that could be applied in a mobile phone camera to further reduce the device thickness.

“We have used the thinnest material in the world to fabricate a flat lens and prove that the good performance of the ultrathin lens can lead to high resolution imaging,” says Professor Jia.

“It shows enormous potential in different applications. Using this technique, the weight and size of camera lenses could be significantly reduced,” says Professor Chengwei Qiu.

Professor Qiaoliang Bao adds: “We are excited to see unique outcome from femtosecond laser nanoprinting of 2D materials. It opens up new possibilities to fabricate photonic devices using a scalable and low-cost method. This lens is readily integratable with existing devices.”

-

Media Enquiries

Related articles

-

- Technology

- Science

- Engineering

Victorian students drive green energy transition through international hydrogen competition

Swinburne’s KIOSC, in collaboration with Horizon Educational and Gippsland Tech School, co-hosted the Hydrogen Grand Prix in Melbourne.Friday 26 July 2024 -

- Technology

- Health

New MedTechVic prototypes to transform everyday lives of people with a disability

Swinburne’s MedTechVic has revealed three new prototypes designed through the joint Health-led Manufacturing Innovation Program, in partnership with the Australian Medtech Manufacturing Centre and Safer Care Victoria

Friday 19 July 2024 -

- Science

Skin, scales and fish tails: using collagen to turn fish guts into gold

New research from Swinburne could transform the sector by converting high value collagen proteins from seafood by-products into cosmetics, food, and pharmaceuticals.

Tuesday 02 July 2024 -

- Science

- Engineering

Submarines in the future could self-identify cracks and self-heal thanks to Swinburne researcher

Thanks to the work of Dr Nisa Salim from Swinburne University of Technology’s School of Engineering, future submarines could self-identify microcracks and self-heal using a new kind of carbon fibre reinforced polymer composites.

Monday 17 June 2024 -

- Business

- Technology

Swinburne’s Luminate Pitch Night 2024 advances innovative ideas for a better world

Swinburne’s 2024 Luminate Pitch Night showcased market-ready ideas from 10 founders

Wednesday 12 June 2024