Mosquito zapper recognised by James Dyson Awards

In Summary

- Swinburne student is a runner-up in the Australian national James Dyson Awards

- Designed a mosquito zapper that runs on renewable energy and helps stop spread of diseases

Swinburne product design engineering student Paul Eterovich’s unique device to help stop the spread of mosquito borne diseases has been recognised by the James Dyson Awards.

Mr Eterovich was named one of two Australian runners-up in the prestigious design competition for his Indra Mosquito Zapper.

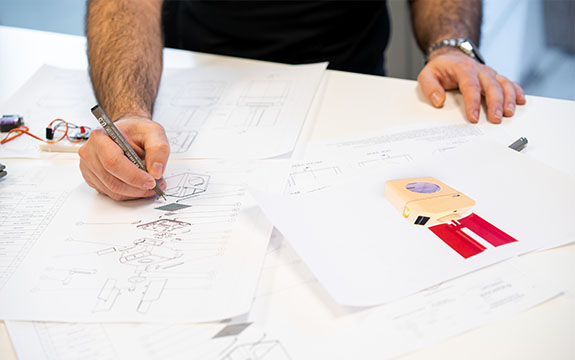

The Indra Mosquito Zapper is an insect control device made from recycled materials. Powered by wind and solar energy, the device creates electricity to zap and kill mosquitoes. Once fully charged, the stored electricity also creates light and can charge electronic devices through its USB port.

“I feel a sense of accomplishment to have my design acknowledged,” says Mr Eterovich.

“There have been many challenges along the way, but my hard work and passion for creating have enabled me to overcome them. The recognition of the James Dyson Award is a great opportunity to reflect on what I have achieved so far.“

Real-world impact

Mr Eterovich was inspired to tackle the endemic problem of mosquito borne diseases (MBDs), such as malaria and dengue fever, which are a major public health problem in India, particularly to street vendors.

As much as 65 per cent of the population at risk of becoming infected with malaria in South-East Asia reside in India. And between August and September 2015, there were 2,818 cases of dengue fever in Gujarat. Existing methods to prevent MDBs can be inconvenient and toxic.

The objective of Mr Eterovich’s design project was to provide people with an inexpensive and safe way to decrease the number of mosquitos and other pests where they work and live.

The Swinburne experience

His achievement follows Swinburne’s success last year in which a student team was shortlisted for the international James Dyson awards.

“Studying at Swinburne has strengthened my ability to take a design from an abstract concept to a manufactured product,” says Mr Eterovich.

“I have learnt solid design skills from teachers who are familiar with current industry practices and techniques and had access to a well-equipped workshop with knowledgeable and helpful staff.”