Designers at Swinburne create 3D printed pendant lights for LimeLite

In Summary

- Limelite pendant lights are made from just two to three 3D printed parts

- 3D printing technology makes it easier to achieve an advanced level of geometric complexity

- Designed to have a timeless style and aesthetic, the pendants are a stand-alone statement fitting

After recently designing a range of 3D printed track lights for LimeLite, Swinburne designers have partnered with the manufacturer again to create a stunning range of pendant fittings.

The pendant collection is designed for manufacture using 3D printing technology. LED technology is used to provide a large range of lighting temperatures with remote control.

The lights have been designed as statement fixtures, featuring complex geometries not usually possible with traditional manufacturing processes used in the lighting industry. Each light is made using two to three 3D printed parts.

Geo Arc pendant light.

Geo Arc pendant light.

Lantern pendant light.

Lantern pendant light.

Product designers at the Centre for Design Innovation created a total of five lights for LimeLite. Three are currently in production and are commercially available. The lights are manufactured on the same 3D printer production lines developed for LimeLite’s track lighting range.

“As a manufacturing method, 3D printing allows you to create aesthetically complex geometries that are otherwise unachievable with traditional manufacturing technology. Products are designed with inbuilt features, reducing or replacing the number of fixtures required, such as screws and bolts,” says Chair, Interior Architecture and Industrial Design at Swinburne School of Design, Professor Blair Kuys.

“After designing the first lighting range we were more conscious of creating forms that could be printed with minimal support structures. This was crucial in reducing the assembly time and labour required for post-processing each 3D print, allowing the client to price his products more competitively,” says Professor Kuys.

Geo sphere pendants, image by Centre for Design Innovation

Geo sphere pendants, image by Centre for Design Innovation

The pendants were designed to have a timeless style and aesthetic as a stand-alone statement fitting. The lights appear delicate and fragile but they are robust and can withstand the rigours of everyday use. The intricate forms would usually be complex to manufacture using traditional methods.

“To experiment and test the illumination patterns created by the intricate forms, we used simple tests, shining a light through a random 3D print to see how the print would glow or how the light would catch on an edge. We would then try to replicate that effect in the designs,” says Professor Kuys.

Testing prototype pendant lights.

Testing prototype pendant lights.

Using 3D printing technology makes achieving this level of geometric complexity much easier. The pendants are more lightweight than most pendants of a similar size as they don’t contain cumbersome metal or glass components.

“The 3D printer's ability to print these complex geometries allows us to integrate multiple parts into a single component. We can produce and explore forms and aesthetics, that are difficult to produce and generally avoided in conventional manufacturing. We were not trying to design something to be complex for complexity’s sake, instead we were trying to fully capitalise on the capabilities of a 3D printer,” explains Professor Kuys.

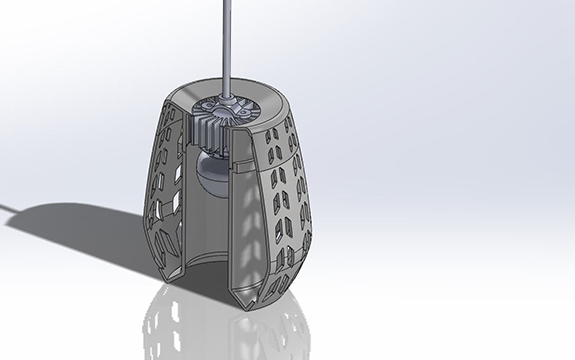

Cut-away drawing of Lantern pendant.

Cut-away drawing of Lantern pendant.

The maximum size the design team were working with for a single printed part was 190 x 160 x 160 mm. To create pendants that were big enough, most of the designs are created in two parts to create this volume. The pendant colours are the original material colour in white or black, no finishes need to be applied. The surfaces are easily cleaned.