Architectural Design focus on materials and making

In Summary

- Swinburne’s inaugural Architectural Design Studio has a focus on materials and making

- Equipping architectural design students for work in an Industry 4.0 environment

- Prototyping is a fundamental activity of the Swinburne Architectural Design program

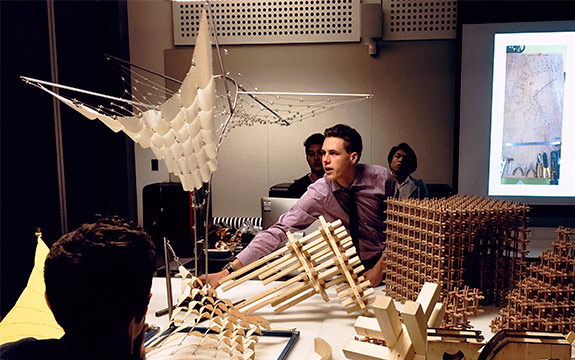

Swinburne Architectural Design students presenting at the inaugural Architectural Design Studio created their work in new state-of-the art workshop facilities and presented to a jury panel in the studio.

The industry and academic members of the jury panel were Finn Warnock, Director of Hachem; Robert Page, Project Director, SHoP Architects; Associate Professor John Sadar, Course Director of Architecture; Professor Jane Burry, Dean of Design; Professor of Architecture Mark Taylor and Dr Drew Williamson, Industry Fellow for Architecture and Director of Campus Space, Swinburne Architectural Design.

Student work in the studio and ready for presentation to the jury

The focus of the Architecture Design Studio is for students to understand and learn about materials. They are encouraged to embrace the act of making as a fundamental activity of architectural design.

Students in the workshop building prototypes

Students start by investigating different construction materials such as timber, concrete and steel. They investigate all aspects of these materials. They learn how they are created, manufactured, constructed and what tools and processes are involved.

Students and instructors in the workshop making prototypes from various materials

“Having access to materials and tools in the workshop, and making things is essential to the learning process at Swinburne. Students need to start from the ground up with a deep understanding of real materials before they can start to design,” says Canhui Chen, Bachelor of Design (Architecture) Lecturer, and Digital Fabrication stream leader at Swinburne.

Students in the workshop working on a scale model with welded frame and metal cable system

In the first half of the semester, students focus on fundamental studies, test and analyse materials and construction techniques. In the second half of the semester, they take this knowledge and start to push the boundaries while conforming to the principles of their chosen construction techniques.

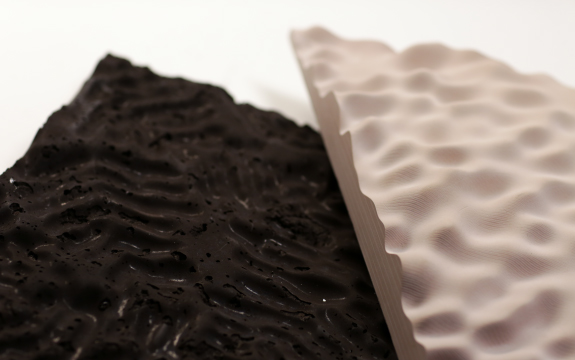

Verde, concrete panels moulded in vacuum formed mould from CNC machined forms by Architectural Design student, Charlotte Mwaba

“For example, concrete needs a mould. But what can the mould be? What pattern? What shapes? Can it be curved?” explains Mr Chen.

Students apply their knowledge of materials and construction to a digital design process to create new designs. Their design concepts push conventional understanding of a material construction technique. They create scale models - detailing connections, construction, pattern, shape or whatever is required, as a proof of concept.

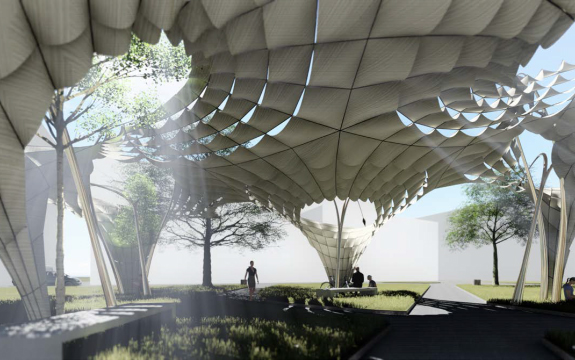

Koi, welded metal, cable with timber panels, by Architectural Design student Nick Aylward

The final work is a pavilion design and a series of prototypes that demonstrate a material choice and construction principle. This is supported by digital sketches, drawings and renderings.

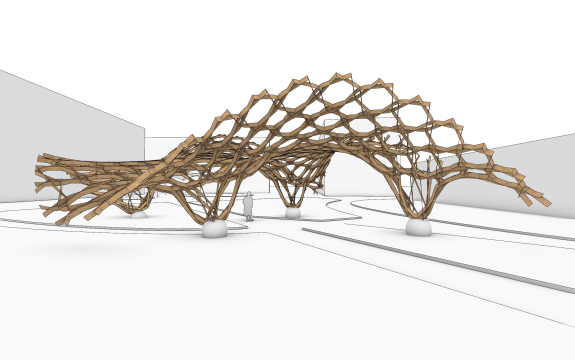

New Wave, curved timber construction and large scale prototype, by Architectural Design student Ralph Santos

“Prototyping is considered a fundamental activity of our architecture program. It equips architecture students with a knowledge of future architectural and construction technologies and the requirements of working in an Industry 4.0 environment,” says Mr Chen.

Tectonic Systems, 3D printed parts, by Architectural Design student Amy Nuccio

The Swinburne workshop has an enviable collection of tools and equipment for students to use. They are able to create three-dimensional models and prototypes to test and visualise their ideas, no matter how complex.

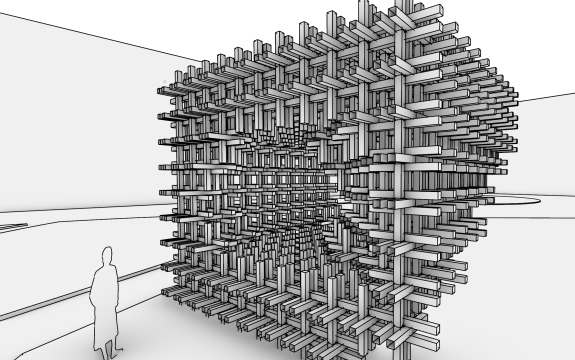

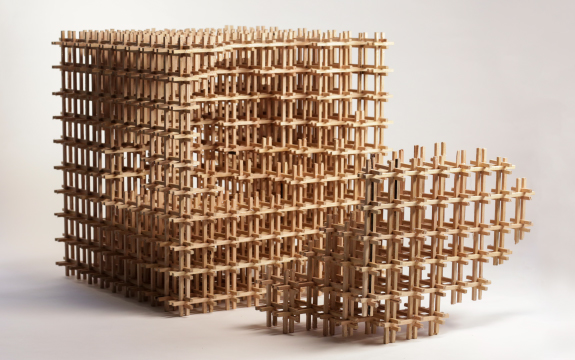

Lattice Pavilion, timber construction, by Architectural Design student Jordan Veniamakis

Architectural Design has a large workshop expansion planned for next year. The extended workshop will provide Swinburne Architectural Design students with 24-hour model making facilities and a prototyping space with advanced equipment including an industrial scale robotic fabrication system.