Research into cleaner batteries backed by $3.45M government grant

In Summary

- Swinburne research into graphene oxide has been backed by a $3.45 million grant.

- Funding comes as part of the Cooperative Research Centres Projects (CRC-P) funds commissioned by the Australian Government.

- Research is a collaboration between Swinburne, Flinders University and industry leaders First Graphite and Kremford.

Swinburne researchers have secured $3.45 million in funding to continue work on a project investigating energy storage alternatives using graphene oxide.

Graphene oxide is the lightest, strongest and most electrically conductive material to be discovered and has the potential to revolutionise manufacturing across all industries.

Researchers will receive the grant as part of the Cooperative Research Centres Projects (CRC-P) funds commissioned by the Australian Government.

The Swinburne Centre for Micro-Photonics is collaborating with Flinders University as well as industry leaders First Graphene Ltd and Kremford Pty Ltd.

The ‘High performance energy storage alternative to lithium ion batteries’ project is working towards creating commercially viable and chemical-free batteries using graphene.

This involves the production of a graphene oxide-based supercapacitor, which will be the world’s first alternative to lithium ion batteries (LIB).

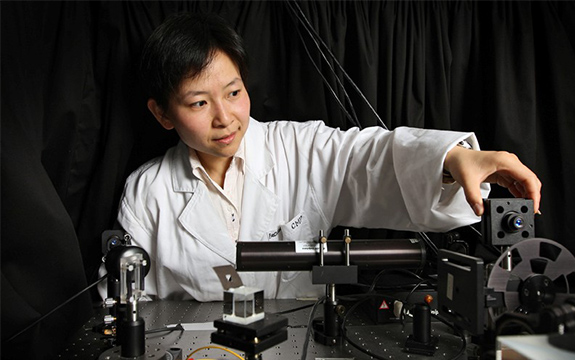

Swinburne Research Leader Professor Baohua Jia leads a team developing the Bolt Electricity Storage Technology (BEST) battery – a graphene oxide-based supercapacitor offering high performance and low-cost energy storage.

“The battery is very thin, it is carbon based and it is environmentally friendly,” Professor Jia says.

“We filed a patent on the technology last year.”

However, unreliable quality and a lack of manufacturing processes has prevented graphene from becoming industry standard.

In October, Swinburne created the world’s first graphene certification centre as part of its revolutionary research into graphene and digital manufacturing processes.

The primary focus of the centre is to develop graphene to the point where it will meet strict quality guidelines and be ready for use in large-scale manufacturing.

Director of the Manufacturing Futures Research Institute at Swinburne, Professor Bronwyn Fox, says Swinburne is at the forefront of graphene research.

“We’re doing everything here at Swinburne from the very fundamental research right through to the translational industrial research in Graphene,” Professor Fox says.

“Smart materials use graphene coated fibres and fabrics that will sense and communicate data.”

Graphene is believed to be central to the next industrial revolution, industry 4.0, which will see the digital transformation of manufacturing processes.

The project received the funding as part of the fourth round of grants awarded under the CRC-P stream of the overarching CRC Program.

First Graphite managing director Craig McGuckin believes the recent funding is testament to the worth of the project.

“The success in the fourth round of the CRC-P funding demonstrates the high regard in which the company’s research efforts are held,” Mr McGuckin told Science Meets Business.

“It also shows the robustness of the programs designed by FGR’s university partners.”