Return to the fold for super-strong structures

In Summary

- This article featured in Swinburne’s 2017 ‘Research Impact’ magazine, produced in association with Nature Publishing Group.

Lightweight structural panels that can stop bullets or withstand bombs are the goal of a team of researchers working at Swinburne.

Since antiquity, engineers have used geometric tricks to improve the performance of load-bearing structures such as trusses and arches. Now, the team led by Professor Guoxing Lu from Swinburne’s School of Engineering has put a modern twist on this ancient science by replacing solid metal panels with super-tough and light aluminium ‘sandwich’ structures inspired by Japanese origami patterns.

A typical sandwich panel inserts a soft, semi-hollow inner core between two thin and strong outer skins. Spacing the skins a small distance apart makes the panels much stiffer than the sheet would otherwise be while dramatically decreasing overall bulk.

“The aerospace industry uses sandwich panels because they work so well in reducing weight,” says Professor Lu. “But increasingly, we’re seeing them in vehicles and civil infrastructure.”

Professor Lu and his co-workers are at the forefront of efforts to use sandwich structures to protect against catastrophic events — a terrorist bombing, for example, or the impact of a plane crash. If designed optimally, the soft, crushable cores of these panels can effectively dissipate energy, while the rigid outer skins resist deformation. The team used high-speed cameras to understand how these innovative materials are affected by ballistic collisions by projectiles or pressure waves from explosions.

Recently, the researchers have had promising results with aluminium foam, a porous metal tougher than traditional cores with exceptional energy absorption qualities. However, the closed cell structure of aluminium foam prevented air and other fluids from moving freely during a blast impact, which affected the panel in different ways.

“Apart from mechanical requirements that they must be strong enough, there can be thermal or acoustic issues with the panels,” Professor Lu says. “If you could combine these factors in the right way, there would be a real advantage.”

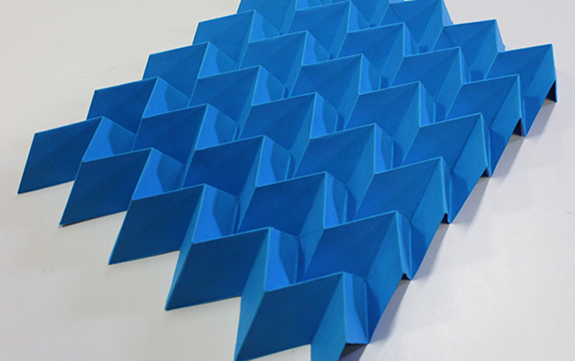

Professor Lu is embarking on a four-year project to create all-in-one sandwich panels by designing cores with specific geometric folds. Engineers are finding that paper origami models are readily adapted into ‘deployable’ structures that switch from compact to expanded structures using simple mechanical motion. With help from collaborator Zhong You at Oxford University in the United Kingdom, Professor Lu aims to use shape-shifting origami cores to improve both energy dissipation and fluid movement in blast-resistant panels.

The team’s initial investigations involved Miura origami, a means of folding flat sheets into peaks resembling mountains and valleys. “We can control the core by adjusting only the geometry, and it enables air to flow freely,” Professor Lu says. “If we prove it offers better performance for the same mass, it could be very useful.”

If successful, the potential applications, for personal safety, building, and aviation, will be significant.