ANFF-VIC Biointerface Engineering Hub

The ANFF-Vic Biointerface Engineering Hub focuses on the use of synthetic and biological components to create materials and surfaces with new properties.

Applications of the technology being researched include implantable devices, cell culture and environmental sensors.

The facility has a wide range of capabilities in surface modification including thin films, polymer grafting, biomolecule immobilisation and bioactive coatings in polymers, ceramics and metals.

Equipment

The hub houses specialised equipment, including:

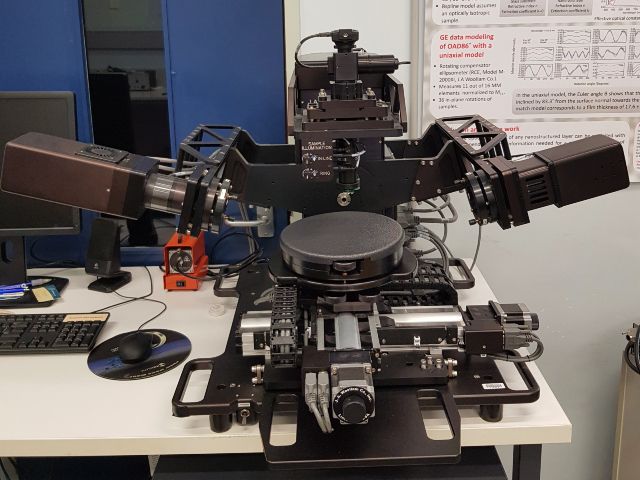

Spectroscopic Ellipsometer (J.A. Woollam M-2000XI)

Spectroscopic ellipsometry is an optical characterisation technique used to determine the thickness of films. Polarised light is shined on the surface, reflected and received by the detector. The changes in polarisation also enable several other parameters to be determined, including roughness, crystalline nature, doping concentration and electrical conductivity.

At Swinburne, our ellipsometer can measure the thickness of films between 2nm and 3µm thick.

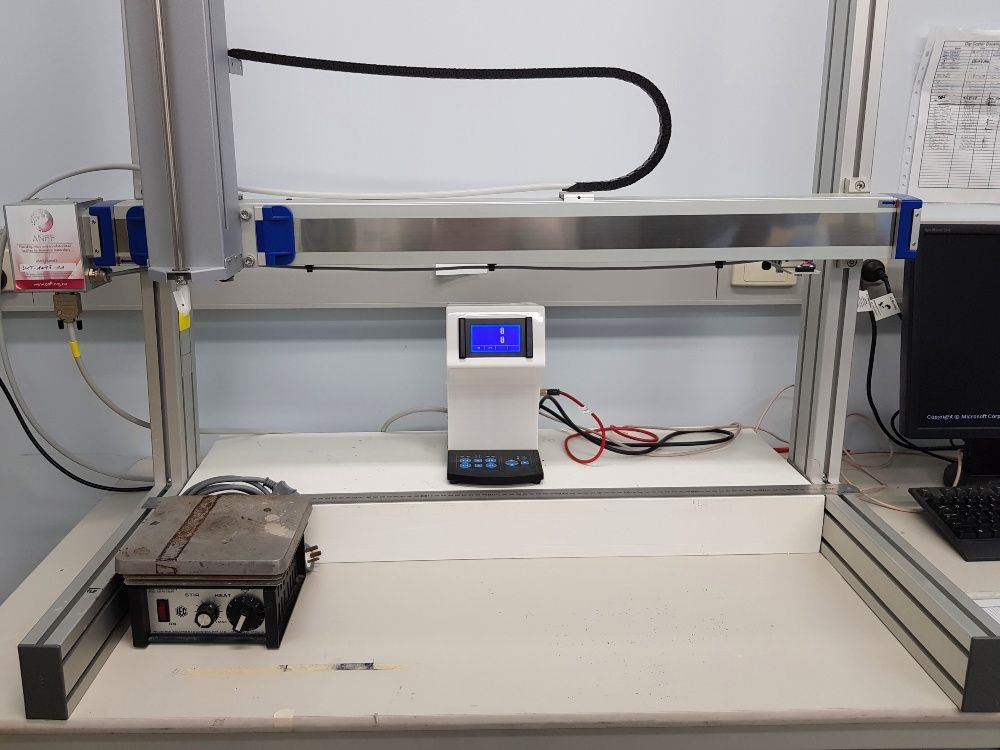

Multivessel Dipcoater (KSV NIMA)

Dip coating is a process to deposit thin films from solution. The substrate is immersed and withdrawn from coating material at a constant speed. A large variety of films can be produced by using either self-assembly, sol-gel chemistry or layer-by-layer assembly.

Different properties of the film can be controlled by varying parameters such as the submersion time, withdrawal speed and number of cycles.

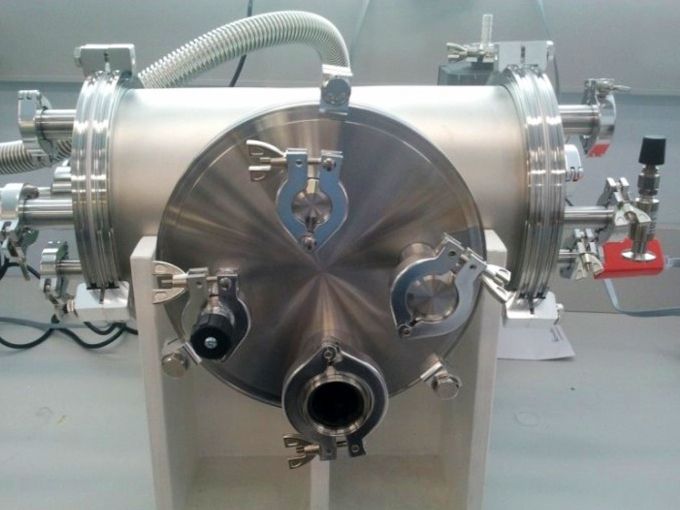

Plasma Polymerisation Reactors

Plasma polymerisation is a technique for modifying the surfaces of materials by adding a thin film which possesses specific functional groups. This technique can produce alkanes, alcohols, acids, amine thiols, PEO-like and fluorocarbons. These functional films can vary the chemistry, charge and wettability of surfaces in addition to how they interact with various biological molecules such as proteins, cells and bacteria.

Plasma is produced by a glow discharge through an organic vapour. This is fragmented using radio frequency. The thickness, structure and surface functionalities of the film can be controlled by varying the plasma power, flow rate and deposition time.

Swinburne has six custom made plasma reactors, each designated for particular surface chemistries or applications. One of the reactors is heated, to enable the vaporisation of monomers with low volatility.

Q-Sense E4 QCM with dissipation (QCM-D)

Quartz Crystal Microbalance (QCM) is used to analyse surface phenomena such as thin film formation, interactions and reactions.

The QCM sensor oscillates at its resonance frequency by alternating voltage. The frequency of the sensor decreases when mass is attached to the sensor. QCM can be used to measure the interactions of proteins, polymers, surfactants and cells with surfaces in solution.

Bioforce Nanosciences UV/Ozone cleaner

A UV/Ozone cleaner removes surface contamination to increase the wettability of surfaces.

It works by irradiating the surface with a mercury lamp, which generates energy in the ultra violet region. This decomposes oxygen molecules and produces ozone. This then decomposes into atomic oxygen, which cleans the surface.

PhD project proposals

We welcome expressions of interest in these projects. Please contact Dr. Karyn Jarvis or Prof. Paul Stoddart to discuss.

Supervisors: Paul Stoddart, Karyn Jarvis

The Australian National Fabrication Facility (ANFF) Biointerface Engineering Hub at Swinburne, specialises in plasma polymerisation. Plasma polymerisation is a versatile thin film deposition technique, which involves the attachment of specific chemistries on a surface via the plasma induced fragmentation of a particular gas or vapour. In this project, a specialised plasma polymer reactor will be used to monitor surface chemistry during the deposition process. In particular, real-time infrared spectroscopy and spectroscopic ellipsometry will be used to gain further insights into the plasma polymer deposition process for a variety of different film types.

Supervisors: Karyn Jarvis, Paul Stoddart

Plasma is considered the fourth state of matter. When it is combined with chemical vapour deposition, it enables unique chemical processes with important technological applications. A new atmospheric plasma system has been acquired as part of our ANFF facility, which will enable surfaces to be modified without the requirement of a vacuum system. Atmospheric plasma is a more industrially-relevant technique which can readily be integrated into existing manufacturing processes. In this project, the various parameters of the atmospheric plasma system will be investigated to gain an understanding of the range of chemistries, hydrophobicity and mechanical properties that can be produced.

Supervisors: Saulius, Juodkazis, Karyn Jarvis, Paul Stoddart, Peter Kingshott

Micro- and nano-patterning of surface chemistry can be used to control the interfacial interactions of biological materials with advanced material surfaces and improve our understanding of how biology and man-made materials interact with each other. Previous work at our facility has shown that dual plasma polymer patterns can be deposited with feature sizes down to a width of 30 nm using electron beam lithography patterning, and with features 60 nm wide able to be visualised using advanced imaging techniques. In this project, a new femtosecond laser etching system and advanced imaging techniques will be investigated to determine the resolutions that can be produced in both single and dual plasma polymer patterns.

Our case studies

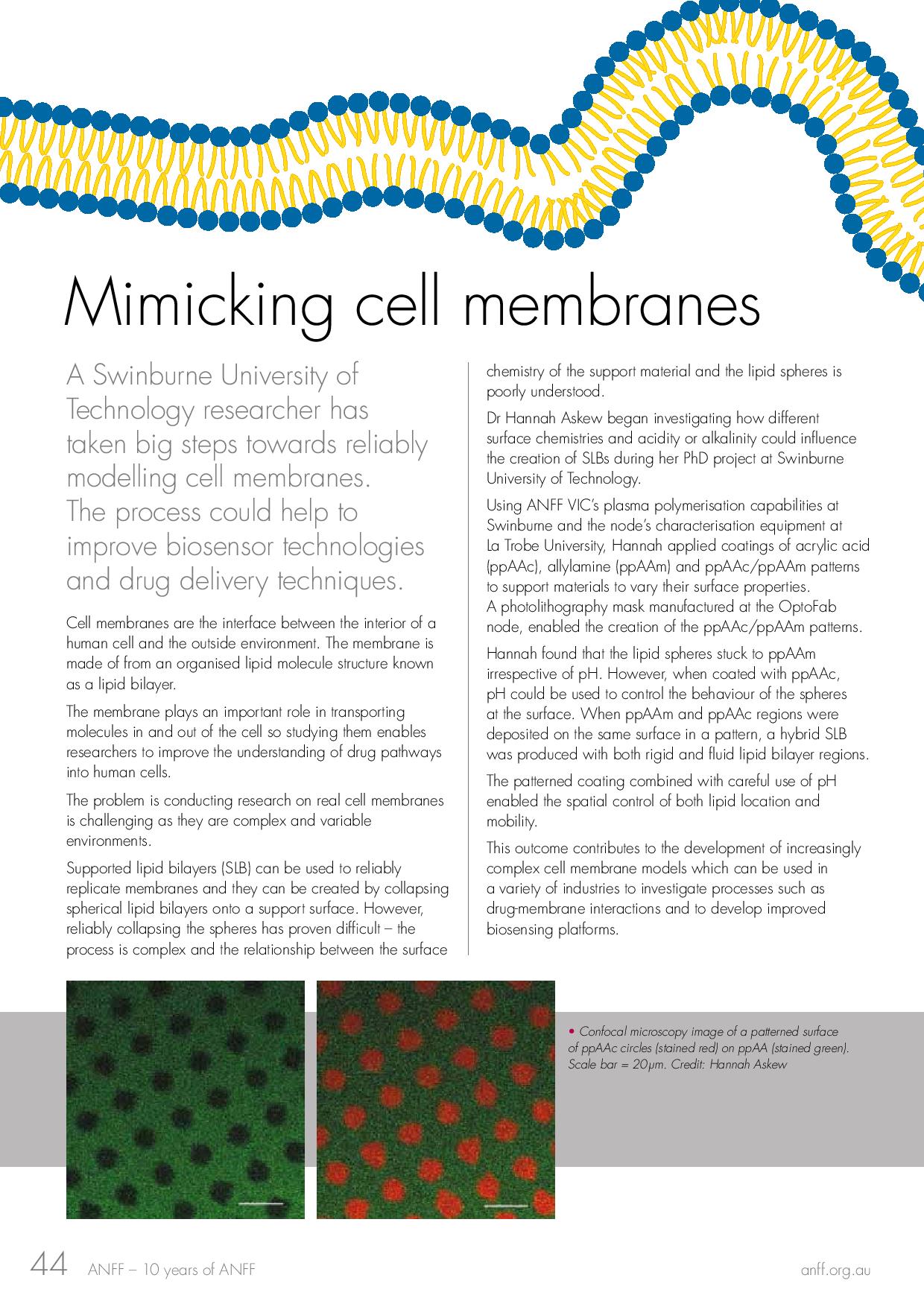

Mimicking cell membranes

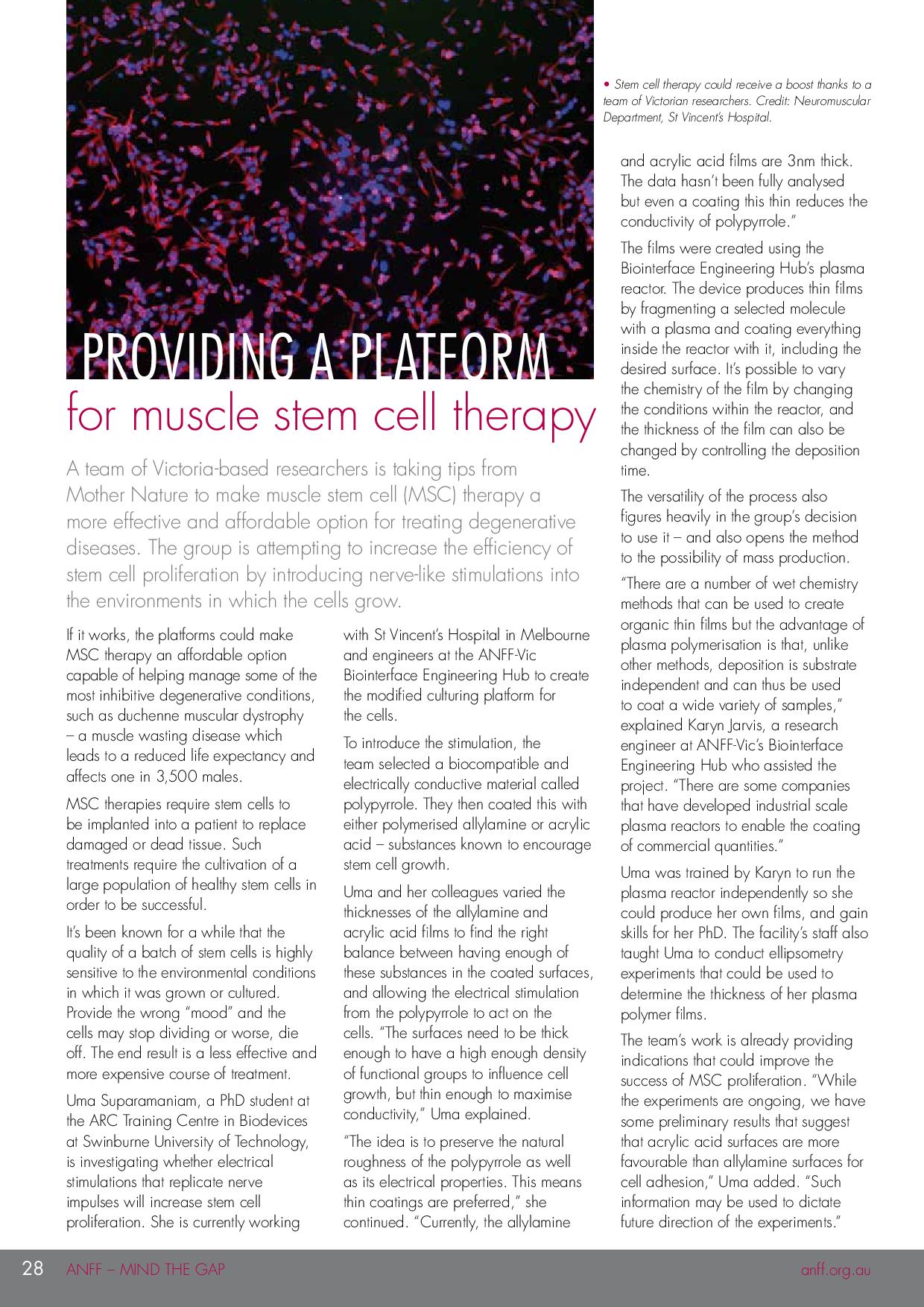

Providing a platform for muscle stem cell therapy

Explore our news

Want to access our facility?

Our laboratory is available for access. Use the online booking system to access the facility or download the ANFF Victoria pricing and access document for more information about access and pricing.

Contact the ANFF-VIC Biointerface Engineering Hub

Whether you’re a PhD student, media or an organisation looking to collaborate and partner with us, please contact either:

Professor Paul Stoddart

Coordinator, ANFF-Vic Biointerface Engineering Hub

Dr Karyn Jarvis

Senior Research Engineer, ANFF -Vic Biointerface Engineering Hub

+61 3 9214 3898

kljarvis@swinburne.edu.au