The XS-310

A lightweight manoeuvrable airtube sprayer for the French viniculture industry.

Global program students at Design Factory Melbourne (DFM) joined forces with Kyoto Institute of Technology to respond to a challenge from Japanese engineering company Yanmar.

Yanmar develops diesel engines, agricultural machinery, power generation, construction equipment and marine vessels. They recognised the need to shift to renewable technologies and electric-powered systems. So, they were looking to identify new product opportunities.

Seeing French vineyards as more traditional and less mechanised, Yanmar identified an opportunity for a new market and wanted to better understand the sector. Their task to the student team: investigate the French viniculture industry.

The Project

Environmentally friendly

The prototype addresses pesticide drift, which spreads dangerous chemicals across the land and to farmers.

Cost-effective

Increased efficiency through double the crop coverage compared with current systems means cost savings

Ground-breaking

The team’s technology collects and recycles stray pesticide particles using a centrifugal fan partnered with a wind curtain.

The Process

The team conducted extensive research with farmers at three separate sites, uncovering two significant issues for the modern vineyard farmer: tractor safety and spraying efficiency.

As research progressed, the team began to focus their attention solely on crop spraying. This involved:

- validating the existing sprayer concepts through analysis, prototyping, and advice from specialists, particularly on spray systems and fluid dynamics

- developing strong relationships with farmers through a co-creative process of integrating, drawing and prototyping

- including farmers directly include them in the outcome.

The team incorporated the research results into a single machine with mechanical, physical, digital and performance properties addressing crucial vineyard farmer needs.

The Solution

The team identified a key concern for farmers and the environment was pesticide drift: when spraying vines, a significant amount of the pesticide is caught on the winds, making the spraying inefficient, and spreading dangerous chemicals across the land and to the farmers themselves.

Incorporating all these considerations into one design, the team produced the XS-310, a proof-of-concept prototype for a lightweight manoeuvrable airtube sprayer that:

- is safer and more environmentally sustainable

- uses groundbreaking technology to collect and recycle stray pesticide particles using a centrifugal fan partnered with a wind curtain

- isolates spray from the ground and the recycling of the spray dramatically reduces pesticide drift

- is more efficient at crop-spraying, achieving double the effective coverage of crops compared with current systems

- is small and manoeuvrable, designed to be attached to a traditional tractor ensuring it will fit into current vineyard practices.

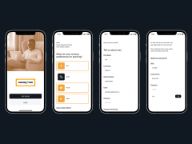

The project also entails the development of an additional digital platform that maps the sprayer’s coverage within the vineyard – thereby allowing farmers to record spray levels live and collect legally required data.

Yanmar has filed a global patent and taken the XS-310 into further research and development with plans to commercialise the technology.

Keep on exploring

-

Metaflora

A Swinburne Design Factory Melbourne student team developed an innovative, data-backed plan to eradicate hospital food waste by 2030

-

Carelink

A smart mattress that detects and prevents incidents in aged care homes.

-

Money & Me

Swinburne Design Factory Melbourne students collaborated with TOM:Melbourne and Untapped Group to improve banking accessibility for neurodiverse people.

Subscribe to our events and updates

Have any questions?

Get in touch with us to see how we can help with your innovation efforts.