Impact Engineering Laboratory and Facilities

The Impact Engineering Laboratory here at Swinburne is Australia's leading research group for studying the behaviour of innovative materials and structures under dynamic/impact loadings. The Laboratory was founded by Professor Guoxing Lu, with financial support from a number of research grants from the Australian Research Council and industries.

We specialise in dynamic material testing, material characterisation, structural and product drop tests, ballistic projectile penetration tests as well as computational simulations of various dynamic processes.

We also provide material and structural testing services to not only researchers at Swinburne, but also researchers in other universities, research organisations and industries.

Research is focused on investigating energy absorption of light-weight materials and structures, exploring new paradigms for material and structural behaviour and exploiting optimal design for novel structures under various loadings.

-

Two engineers using a high speed camera.

Two engineers using a high speed camera. -

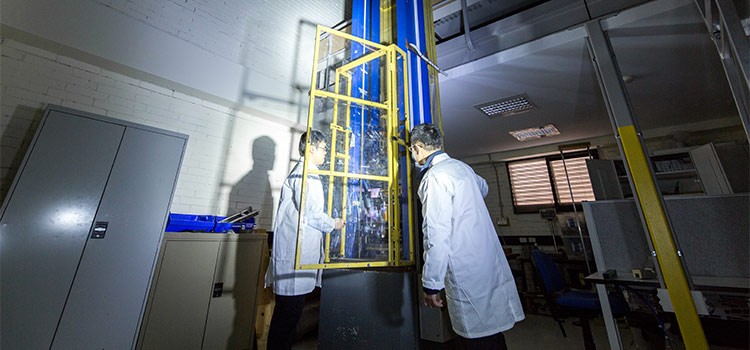

Two engineers using a gas gun inside a laboratory.

Two engineers using a gas gun inside a laboratory. -

The staff of the Impact Engineering Facilities.

The staff of the Impact Engineering Facilities. -

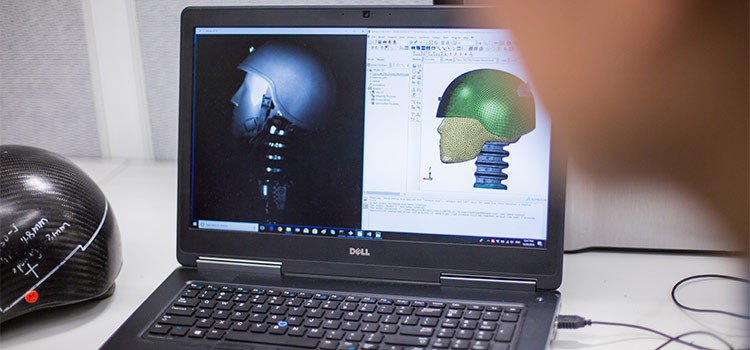

Rendering a virtual helmet.

Rendering a virtual helmet.

Laboratory facilities

Our Impact Engineering Laboratory features a range of equipment that ranges from a very high speed Iinstron machine to gas guns, high speed cameras, pressure bars and laseroptical systems.

To access our facilities please contact Professor Guoxing Lu via glu@swinburne.edu.au.

Very high speed (VHS) Instron machine

- Capacity: up to 60kN

- Capable of velocities: up to 25m/s in tension ad 10m/s in compression

- Specialised measurement transducers

- High speed data acquisition package

- FastTrack™ VHS8800 controller

- FastTrack™ High Rate software

- Systems contained by a protective enclosure to ensure operator safety

- Stiff load frames

- Unique actuator packages featuring hydrostatic bearings, hydraulic end cushions and a seal-free design

- Operates at a 280 bar supply pressure which results in higher acceleration velocity and load performance.

Drop Tower

- Maximum drop height: 3m

- Maximum drop weight: 150kg

- Maximum velocity: 7.5m/s

- Used to conduct dynamic tests of structures (tubes and panels).

37mm split Hopkinson pressure bar (SHPB)

- Type: 37mm SHPB for dynamic compressive tests

- Maximum strike velocity: 25m/s

- Strain rate: 10~104

- Strike bar length: 0.4m, 0.6m, 0.8m and 1m

- Incident bar diameter: 37mm, 50mm, 74mm

- Data acquisition: strain history, velocity of strike bar

- Materials tested: dynamic properties of aluminium foams and concrete.

- Type: 14.5mm SHPB for dynamic compressive tests

- Maximum strike velocity: 25m/s

- Strain rate: 10~104/s

- Temperature: up to 600ºC

- Strike bar length: 0.1, 0.2m, 0.3m and 0.4m

- Incident/transmitted bar diameter: 14.5mm

- Incident/transmitted bar materials: high strength steel and aluminium

- Incident/transmitted bar length: 1.2m

- Data acquisition: strain history, velocity of strike bar

- Materials tested: dynamic properties of metals, composites and concretes.

- Type: 12.7mm SHPB for dynamic compressive tests

- Maximum strike velocity: 30m/s

- Strain rate: 10~104/s

- Strike bar length: 0.12m, 0.2m and 0.3m

- Incident bar diameter: 12.7mm

- Data acquisition: strain history, velocity of strike bar

- Materials tested: dynamic properties of metals, composites and polymers.

- Type: split Hopkinson bar for dynamic tensile tests

- Maximum strike velocity: 25m/s

- Strain rate: 10~104/s

- Strike bar length: 0.15, 0.25m and 0.35m

- Incident bar: Φ19*2850mmtTransmitted bar length: Φ19*1200mm

- Data acquisition: strain history, velocity of strike bar

- Materials tested: dynamic properties of metals and composites.

- Type: one-stage gas gun

- Barrel length: 6m and 8m

- Barrel bore: 12.7mm

- Propellant gas: pressurized Nitrogen and Helium

- Maximum operating pressure: 15MPa

- Maximum muzzle velocity: up to 1000m/s

- Data acquisition: velocity of projectile

- Past experiments: dynamic properties of aluminium honeycombs, penetration properties of aluminium foams and sandwich structures.

Phantom v2512

- Speed: over 25,000 frames-per-second at full resolution

- Up to 663,250 fps at reduced resolutions

- ISO Mono 32,000D* 100,000T

- Ultra-fast 10GB ethernet for fast downloads.

Photron Fastcam APX RS

- Full resolution (1024×1024) up to 3000fps, 128×16 at 250,000fps

- Image sensor: 30-bit color CMOS sensor

- Global electronic shutter: 2µs

- Memory segment feature: 64 different recordings to be made in one session

- Memory size: 10GB.

- Types: optoNCDT 1607, optoNCDT 1607

- Maximum speed: 37KHz

- Measuring ranges: 0.5 - 200mm

- Linearity: 0.2% FSO

- Compact sensor design

- Tiny measuring spot for small targets: 100μm

- Operation with 24 VDC supply: 10 ... 30V

- Output: ±10 V and 4 ... 20 mA and RS232.

- Type: MTS 819

- Force capacity: 250kN

- Data acquisition: force history, displacement history

- Standard tests: quasi-static compression, tension and bending

- Past experiments: compression, shear, tri-axial compression and tension test of aluminium foam.

Swinburne's High-Performance Supercomputer, Ozstar

107 Standard compute nodes:

Dell R740 14G Server:

- 2 x Intel Gold 6140 18-core processors

- 2 x NVIDIA P100 12GB PCIe GPUs

- 192 GB DDR4 RAM

- 400 GB local SSD

8 “Data Crunching” nodes:

- 4 with 384 GB RAM

- 4 with 768 GB RAM

- 2 TB NVMe flash SSD

- Same processors and GPUs as Standard nodes

4 Intel Xeon Phi (KNL) nodes:

Each with 68 core Xeon Phi C6320p

- 100 Gb/s OmniPath interconnect

- 5 PB Lustre-zfs file system

- Slurm workload Manager

- CentOS 7.4 operating system

Lenovo ThinkStation P720

- Windows 10 Pro

- 2x (Dual) Intel Xeon GOLD 6128 Processor (19.25MB Cache, up to 3.70GHz) total 256GB RAM (8 x 32GB) DDR4 2666MHz ECC RDIMM

- HDD 1: 512GB solid state drive, M.2, PCIe, Opal

- HDD 2: 2TB hdard drive, 7200RPM, 3.5, SATA3

- NVidia P4000 8GB dedicated graphics 4x DP HP L_EXT

- Integrated 9-in-1 multimedia card reader

- 2x port integrated ethernet

- Integrated audio.

Related courses

-

Advanced Manufacturing Technology

Manufacturing industries have completely transformed in the past hundred years — and the pace of change will only increase in the next hundred.

-

Mechanical Engineering

Combine physics with materials in our Mechanical Engineering courses, and learn to put your knowledge into practice. Find the right course for you now. -

Product Design Engineering

Best-selling products don’t just happen. Our product engineering courses teach the technology, methods and materials that turn great ideas into reality.

Explore our related research centre

-

Design, Manufacturing and Mechanics Research Group

The Design, Manufacturing and Mechanics Research Group (DMM-G) conducts cutting-edge multidisciplinary research in the area of engineering mechanics and advanced manufacturing and design with an international reputation of excellence.

Contact the Impact Engineering Laboratory team

Whether you’re a PhD student, media, or an organisation looking to collaborate, partner or access our facilities, please contact Professor Guoxing Lu, Director of of Impact Engineering Laboratory and head of research group of Mechanics of Materials and Structures, via glu@swinburne.edu.au.