High Temperature Processing Facility

The High Temperature Processing Facility is used for the research and development of high temperature materials and minerals processing, and includes high temperature and solar thermal laboratories.

Robert Simpson High Temperature Laboratory

A generous gift in memory of one of Australia's leading furnace engineers, Robert (Bob) Simpson, provided Swinburne with the funds to establish the High Temperature Laboratory in the Advanced Technologies Centre.

High temperature processes are an essential element of advanced industrial societies and they dominate energy, metal and materials production. They are also key to developing a sustainable materials industry through the development and optimisation of recycling processes and the containment and processing of waste generated from these processes.

State-of-the-art induction and resistance furnaces

- vertical and horizontal tube resistance furnaces, Nabertherm with Edwards vacuum pump

- muffle and oven furnaces, Nabertherm

- Gero horizontal furnace with Turbomolecular pump

- Ambrell Ekoheat ES, induction furnace 35kVA

Special analysis equipment for studying the changes in matter at high temperatures

- STA (Simultaneous Thermal Anlayser) Setsys Evolution SETARAM equipped with Pfeiffer Thermostar mass spectrometer

High temperature microscopes for observing reactions at high temperatures

Zeiss microscope with high temperature stage (up to 1500°C)

Access our equipment

For enquiries about the equipment listed above, contact Professor M Akbar Rhamdhani on + 61 3 9214 8528 or via arhamdhani@swinburne.edu.au.

Solar Thermal Research Laboratory

Our in-house designed solar simulator here at Swinburne includes an array of seven 6-kilowatt lamps used to mimic the sun. Housed in the Solar Thermal Research Laboratory at the Advanced Manufacturing and Design Centre, we have been using the solar simulator to study the potential of solar energy to smelt metals. It has the potential to develop processes at extremely high temperatures (approaching 2000°C) for application to materials such as iron ore, glass or cement.

There are only three simulators of this kind in the world and Swinburne's is the only one in Australia. Solar simulators have conventionally been made using Xenon arc lamps but these often have a higher intensity of light than is required and can be prone to explosions.

To resolve this problem, Swinburne researchers designed the simulator with metal halide arc lamps, with great success.

The simulator has already demonstrated how solar smelting is feasible, generating heat of between 1000 and 1500°C, the amount required to produce iron from iron ore.

-

Swinburne's in-house designed solar simulator includes an array of seven 6-kilowatt lamps

Swinburne's in-house designed solar simulator includes an array of seven 6-kilowatt lamps -

Ambrell Ekoheat ES Induction Furnace 35kVA

Ambrell Ekoheat ES Induction Furnace 35kVA -

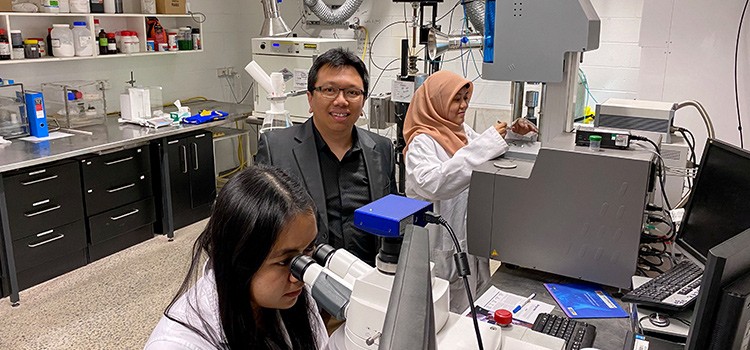

Professor Akbar Rhamdhani, Ms Aulia Qisthi and Ms Bintang Nuraeni using DSC/TGA and high temperature microscope facilities in the Robert Simpson HTP Laboratory.

Professor Akbar Rhamdhani, Ms Aulia Qisthi and Ms Bintang Nuraeni using DSC/TGA and high temperature microscope facilities in the Robert Simpson HTP Laboratory.

Want to access this facility?

It’s available for Swinburne students and staff as well as researchers from other universities to use. Just use our handy online booking system.

Related courses

-

Mechanical Engineering

Combine physics with materials in our Mechanical Engineering courses, and learn to put your knowledge into practice. Find the right course for you now. -

Product Design Engineering

Best-selling products don’t just happen. Our product engineering courses teach the technology, methods and materials that turn great ideas into reality. -

Advanced Manufacturing Technology

Manufacturing industries have completely transformed in the past hundred years — and the pace of change will only increase in the next hundred.

Discover our news

Contact the High Temperature Processing Facility team

Whether you’re a PhD student, media, or an organisation looking to collaborate and partner with us, please contact Professor Geoffrey Brooks on +61 3 9214 5672 or via gbrooks@swinburne.edu.au.