Swinburne and Able Australia develop 3D printed 'Swin Shields'

In Summary

- To help protect COVID-19 transmission among workers in the disability sector, Swinburne engineers worked with Able Australia to produce 3D-printed headbands

- The headbands have fixing points to which plastic page protectors can be attached to form a simple but effective face shield

- The Swinburne team mass-printed 1100 Swin Shields and gifted them to Waverley Industries

In a project to help protect COVID-19 transmission among workers in the disability sector, Swinburne engineers, together with Able Australia, have produced 3D-printed headbands.

The headbands fit commonly found plastic page protectors and form a simple but effective, low-cost face shield.

The coronavirus pandemic gave rise to a shortage of personal protective equipment through the community and what equipment was available was very costly. Able Australia’s CEO Kate MacRae, saw a need for low-cost face shields that could be worn by disability support workers.

“When the first wave of the pandemic hit in March, personal protective equipment (PPE) was in short supply. While the health and aged care sector were given access to the government’s PPE stockpile, the disability sector was excluded. We knew we needed to come up with our own solution,” Ms MacRae says.

“Able Australia, and other disability support providers like us support a significant number of people who fall in the ‘high-risk’ category for COVID-19. Social distancing at all times when supporting someone with a complex disability is virtually impossible. For the safety and wellbeing of our clients and staff we needed PPE and we needed it urgently.”

Together with her husband Richard, Ms MacRae had developed a headband prototype with fixing points matched for a 4-hole punch to which plastic page protectors could be attached, but they were seeking assistance to hone the design and produce a large number.

In April 2020 she engaged Dr Kwong Ming Tse, a researcher in Swinburne’s Department of Mechanical and Product Design Engineering.

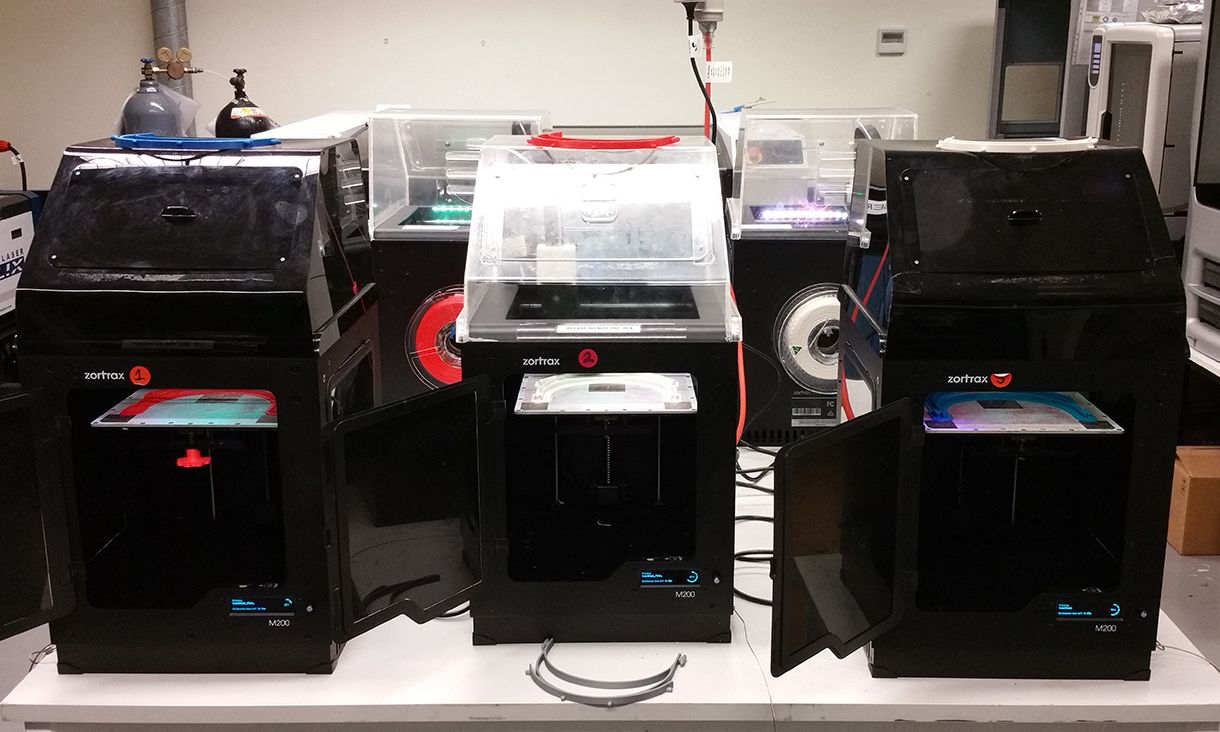

With formal approval from the university to work on campus during the coronavirus lockdown, a team of researchers and technical staff from Swinburne, led by Professor Guoxing Lu and Dr Tse began working on the project.

Dr Tse took the lead in developing the design and worked with technical staff to complete the products.

“After two weeks of initial trials of the face shield prototype, we were able to advance the face shield design to a far more comfortable, user-friendly and safer design, with a shorter printing time,” says Dr Tse.

He took his design with a few earlier prototypes to Vanessa Steele, Group Finance and Corporate Services Manager at Waverley Industries, a not-for-profit organisation that provides employment for people with special needs to try. The new design was found to be the most comfortable.

The Swinburne team mass-printed 1100 of the face shields, dubbed ‘Swin Shields’. The university covered the cost of the 3D printing materials, while the team took care of the 3D printing, product quality and delivering the face shields to Waverley Industries.

Ms MacRae says Swinburne has been incredibly generous in partnering with the disability sector on this endeavour.

“The disability sector really appreciates this partnership and the outcome of increasing safety for staff and clients. This was an amazingly generous offer not only of product but of service and skill too.”

Ms Steele adds: “We thank Professor Lu, Dr Tse and the team from Swinburne for their technical genius in helping us to protect those we support in a safe and affordable manner.”

-

Media Enquiries